Hi All,

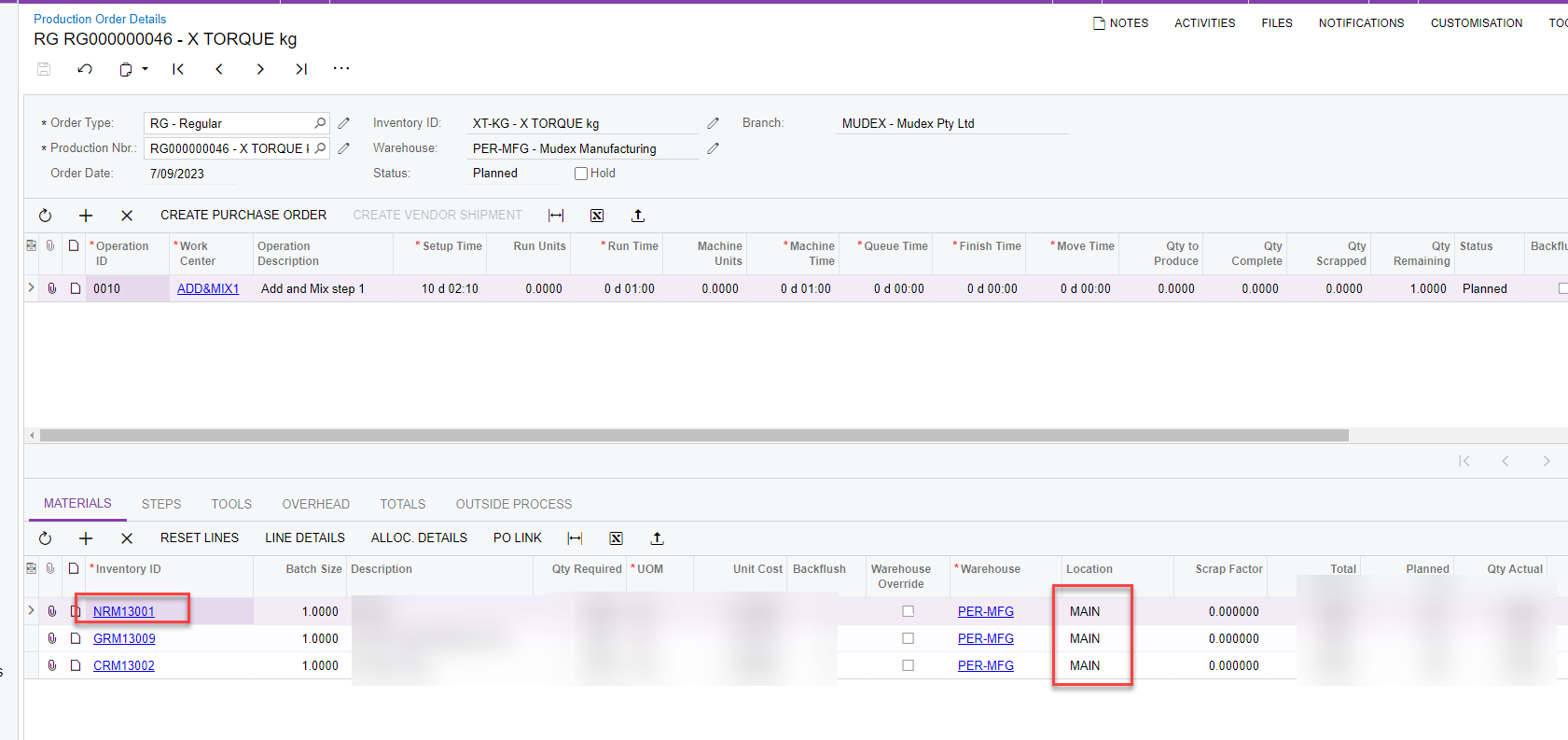

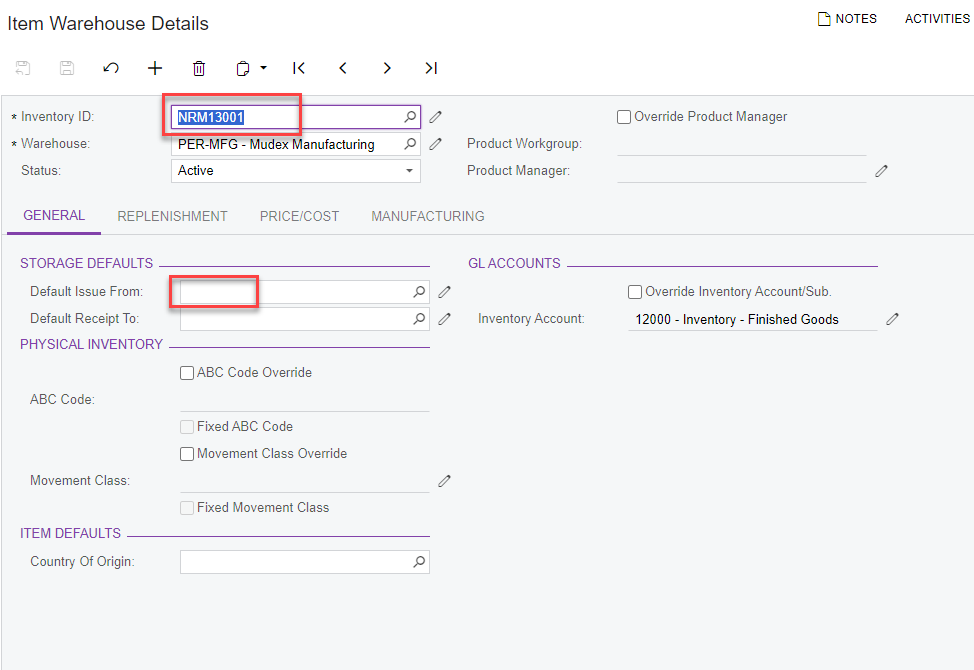

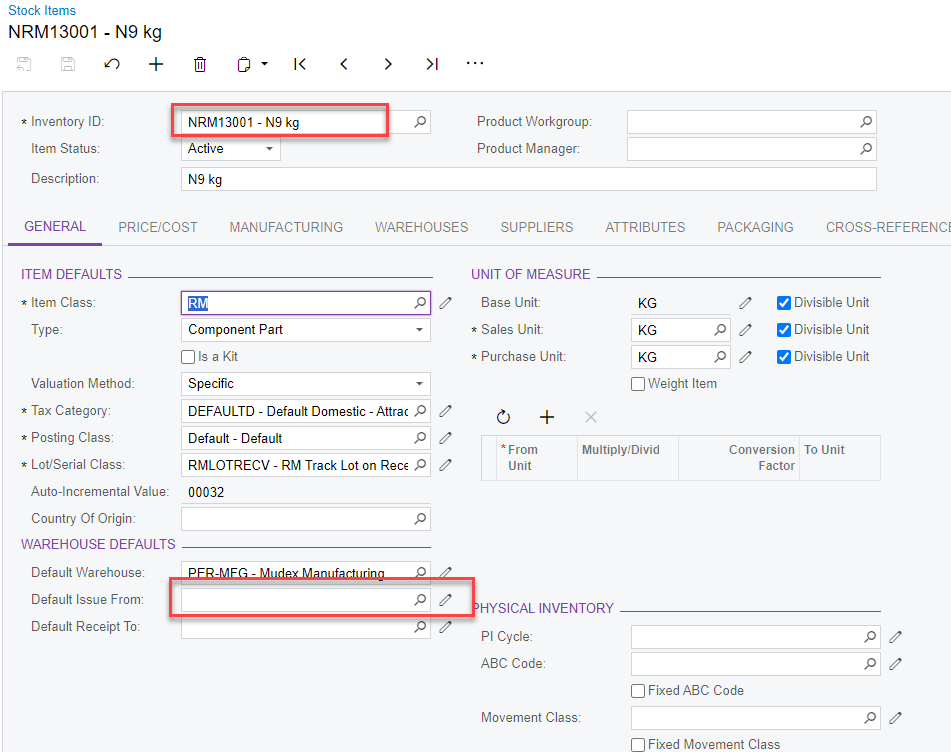

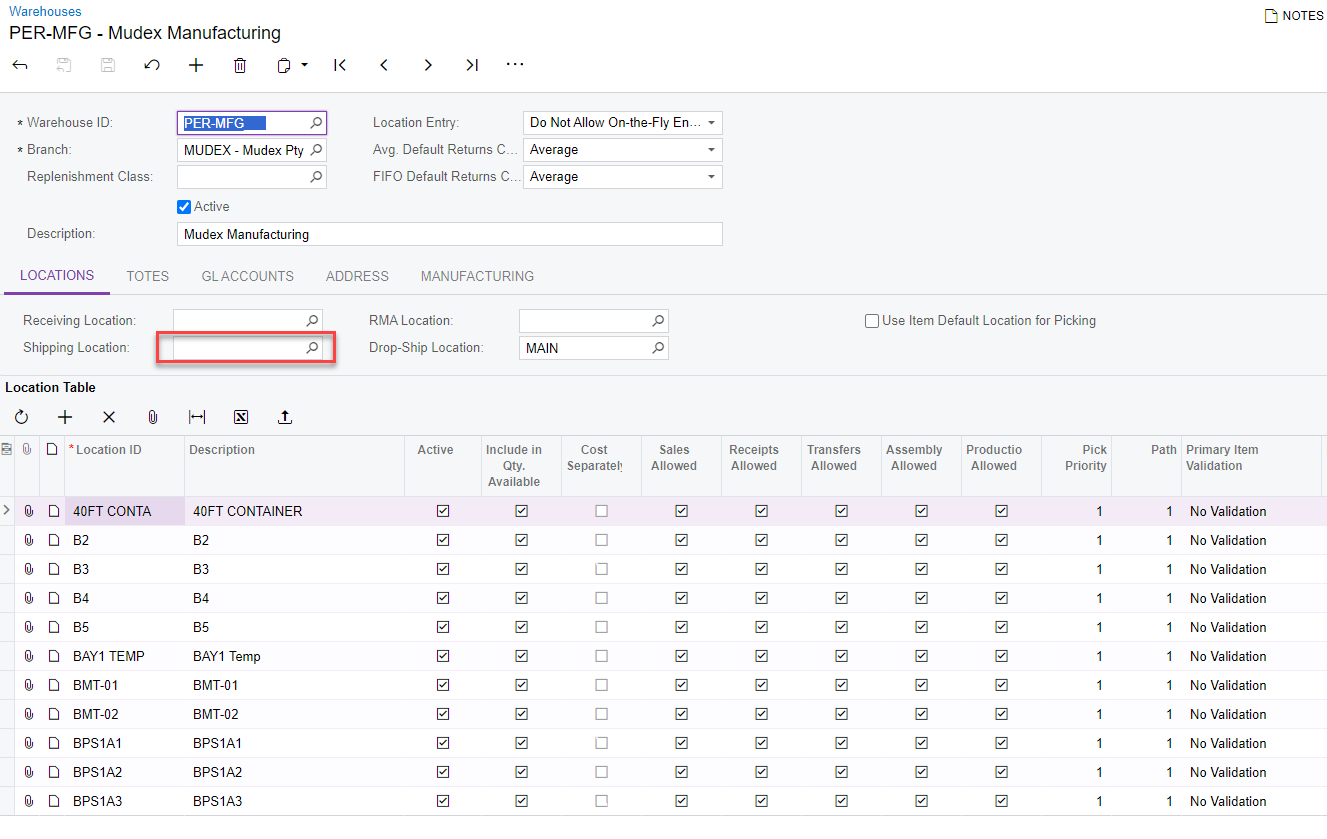

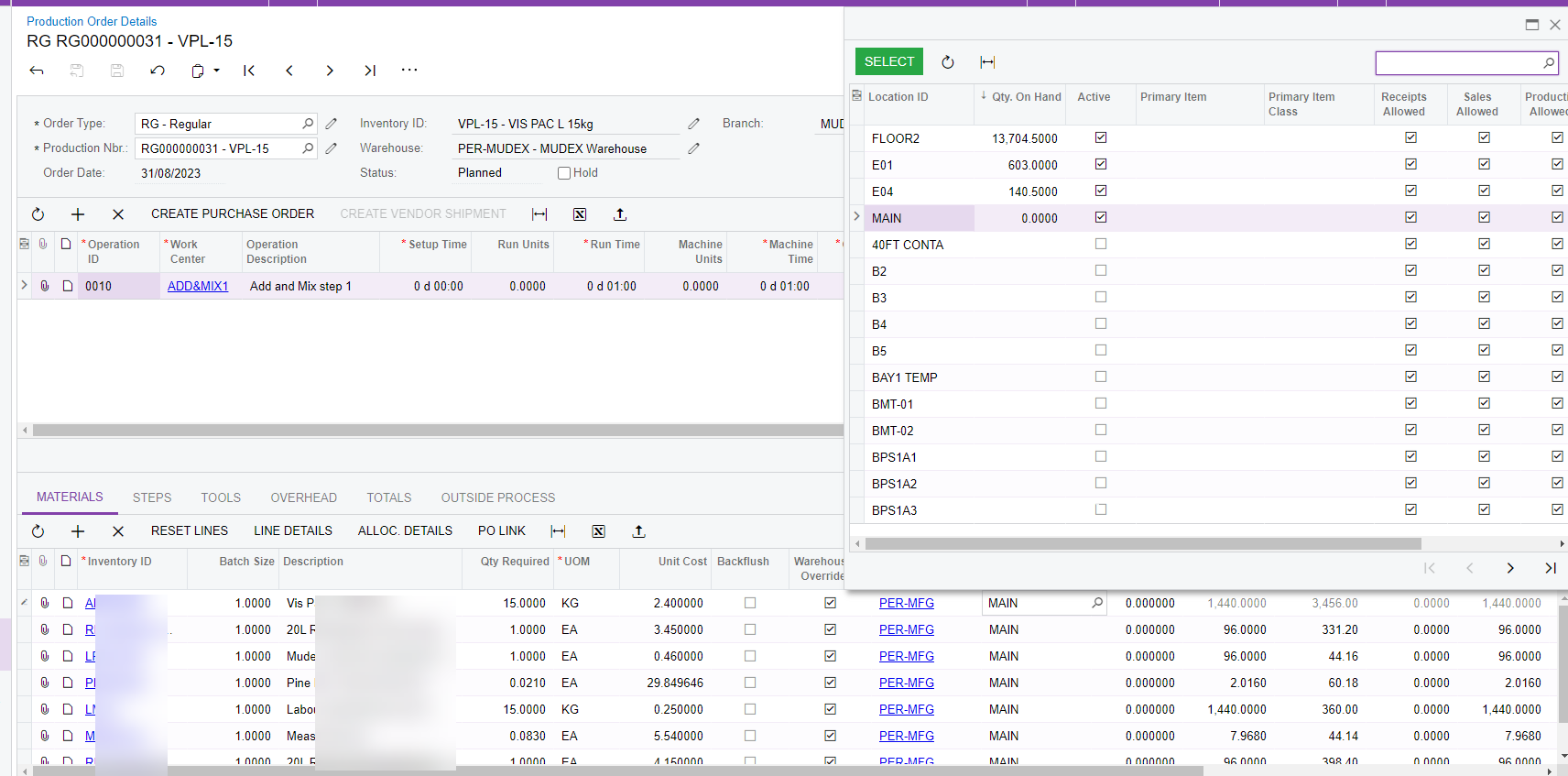

My client is running production in 1 warehouse but materials are stored in multiple locations. they don’t use backflushing and material will be issued using the material wizard. However, the material lines on the Production could be stored in any location in that warehouse. when we run the Wizard if we don’t have enough on hand on that location the line is not brought over to the material screen. so my suggestions were 1:we have to make sure either to transfer the material beforehand (they don’t like this idea as this is adding extra step compared to what they do now) or 2: change the location on the production order detail looking trough the magnifier (they don’t like this either as it is manual) . They use WMS and they say when they create a production ticket that system aslo gives them a picking list for material issue.

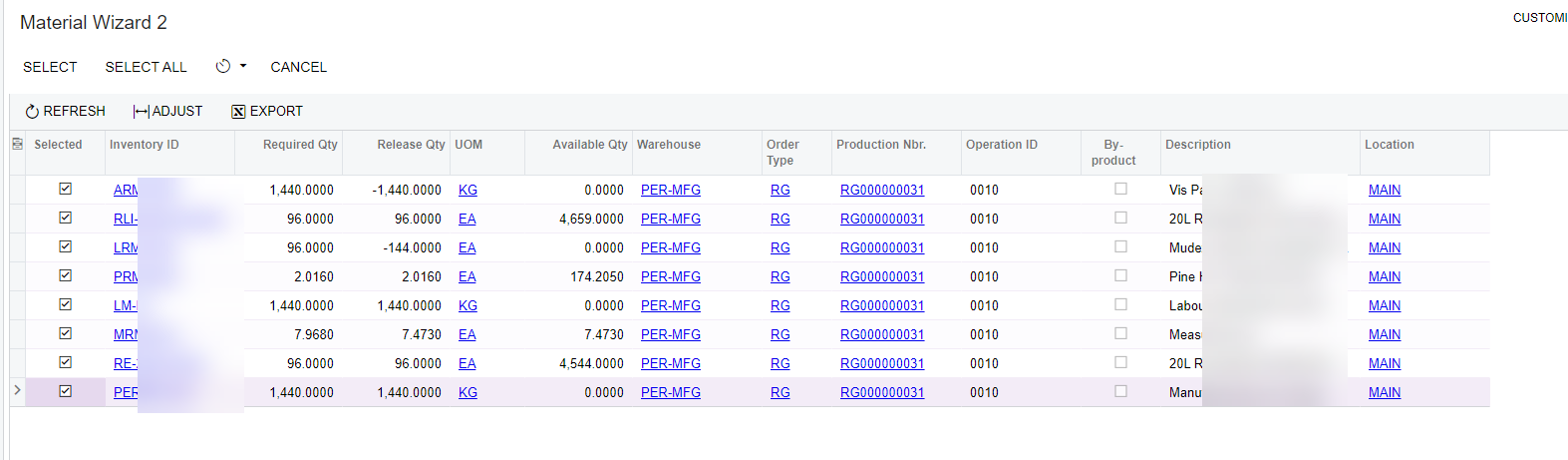

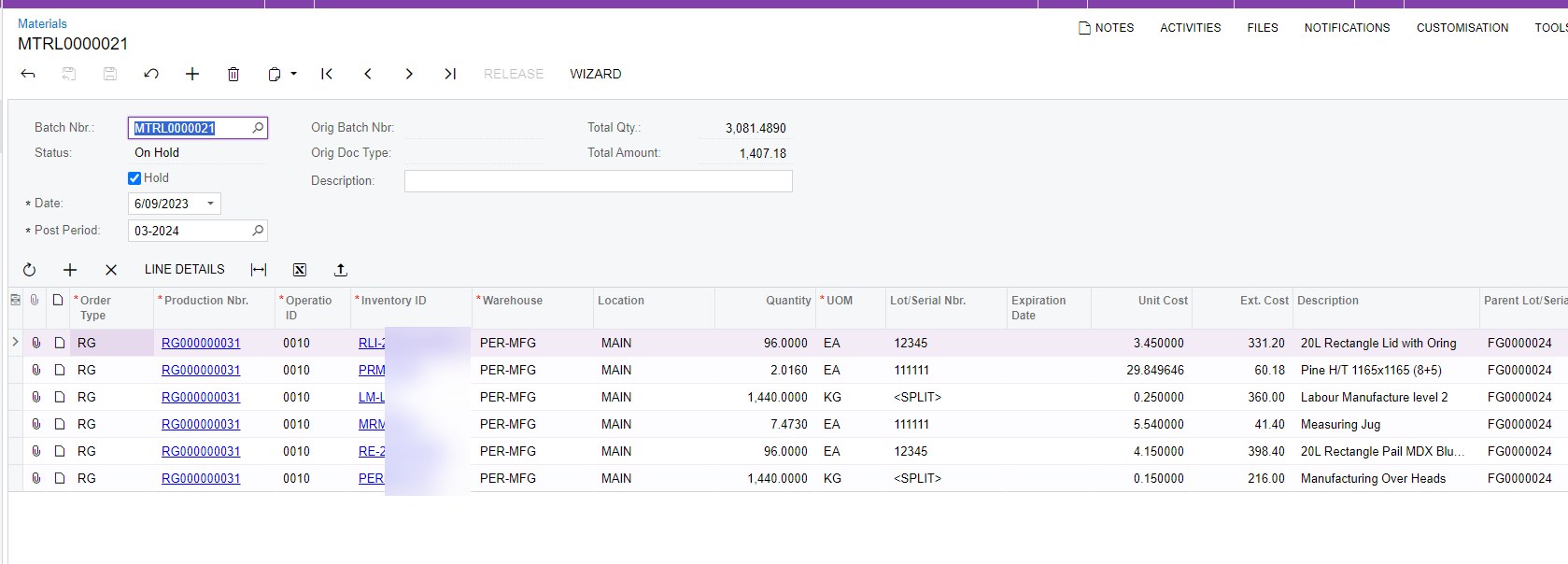

if I don’t chage the Location and leave it to be the main here is what happens:

the Lines which we don’t have enough on hand will not come over and we cannot even change the Location on the Wizard

can someone please suggest to me what I could suggest to this client to streamline this process a bit better?

also what should I be running to know how much material I am below required qty on all the Productions which are happening and looking at that default warehouse?

Thank you for you help in advance

Ghazal