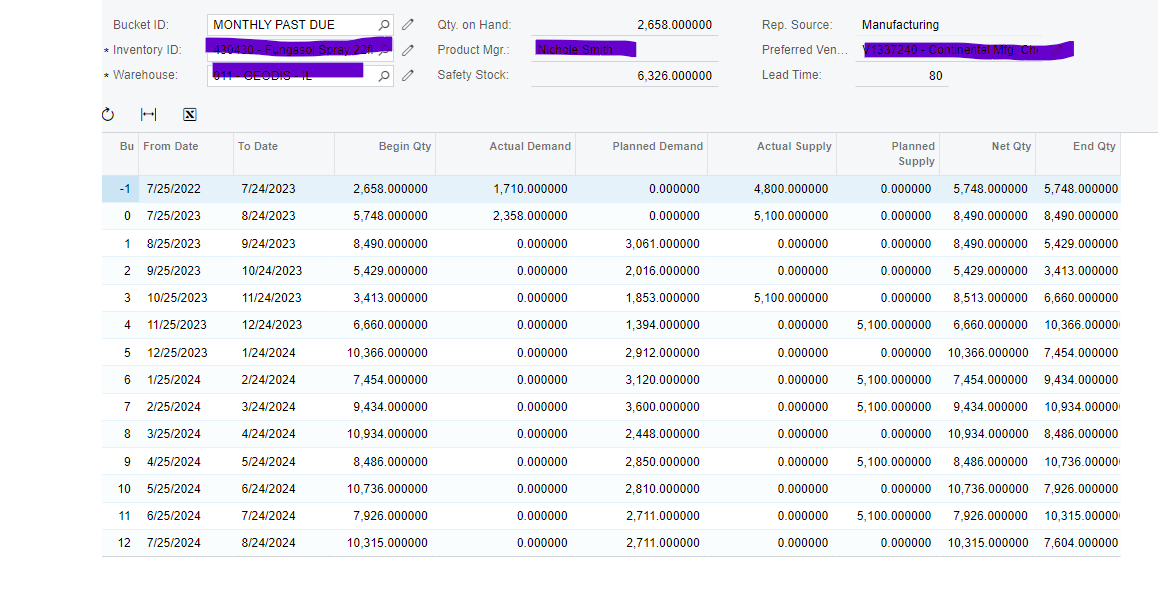

My company is new to Acumatica, and we are having challenges with the MRP Requirements Screen. We have over 200 FG skus to plan and we would like to see an aggregate view of Supply vs. Demand.

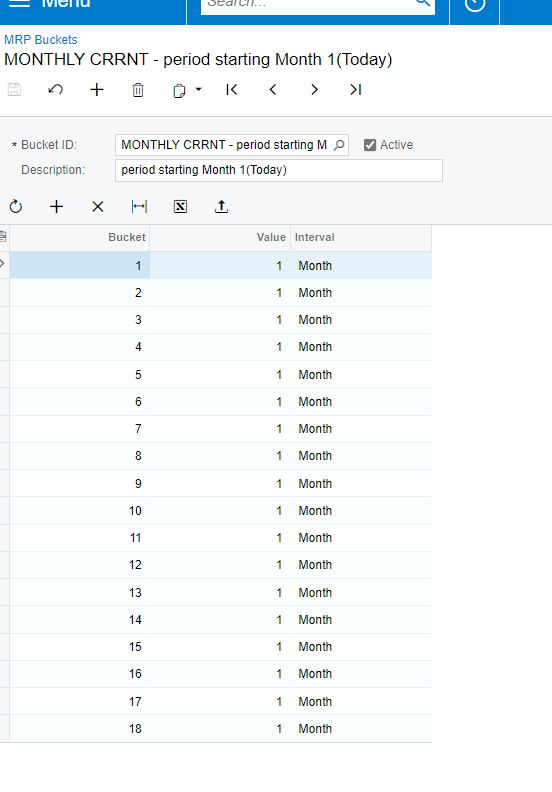

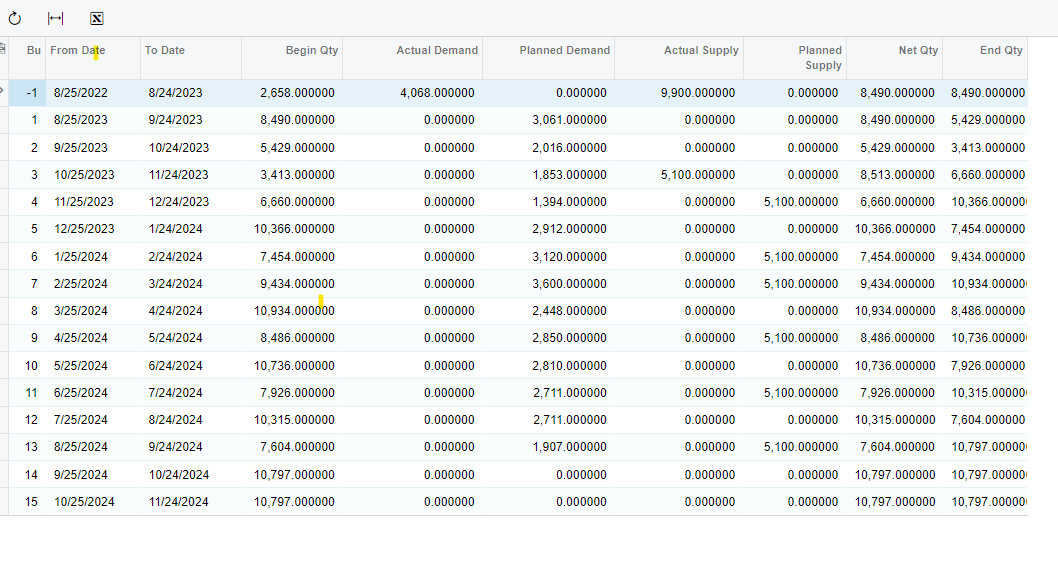

- If we use a Bucket ID with a calendar starting today:

- This screen does not show past due Actual Demand (Customer orders) or Supply (Purchase orders)-then the Ending Quantity goes negative

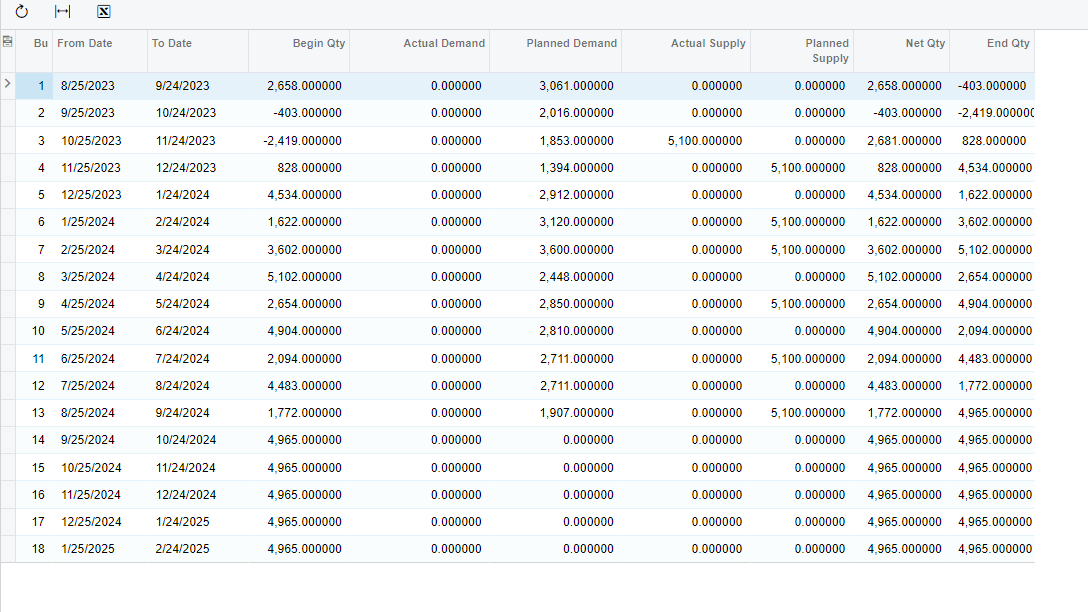

- If we use negative periods to capture the past due Demand and Supply:

- The screen takes the current OH as the starting inventory(Begin Qty) in the past, then we get a different Net Qty and En Qty

My experience with other MRP planning screens it to roll the past due open sales orders and past due purchase/production orders) into today’s bucket and calculate ending inventory from today onward.

- Past dues orders still need to be dealt with via exceptions messages.

- Time buckets should be in Calander dates and not rolling.

Is anyone else struggling with the functionality of this screen?