Hi @di93,

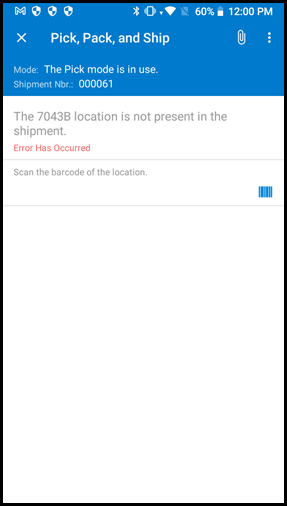

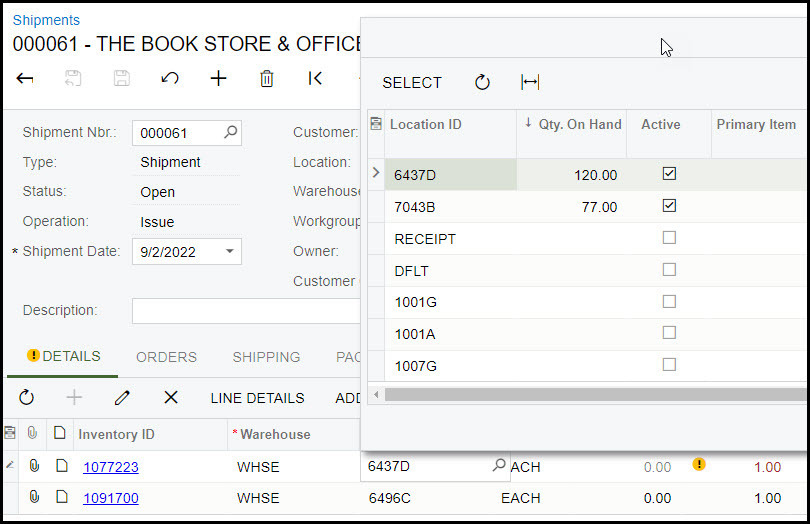

The ability to override the location during picking is on the product backlog to be targeted to a future release. Currently, the location cannot be overridden during picking in handheld. The proposed workaround from meagan59 could be used, albeit that doesn’t help much once picking has started. You could have another worker do a one step transfer to replenish that location with inventory so that the picker could do a full pick from that location and not have to short-pick.

Could we include you in our business requirements process for product improvement. It sounds like you would be able to provide us with valuable input and feedback.

Agree with your comment that inventory does not live in a perfect world.

thanks

-Dana