Hello, can someone point me the right direction to create a leg of another bom within a bom?

Thank you

Zoey

Best answer by jeremyd45

View originalHello, can someone point me the right direction to create a leg of another bom within a bom?

Thank you

Zoey

Best answer by jeremyd45

View originalZoey,

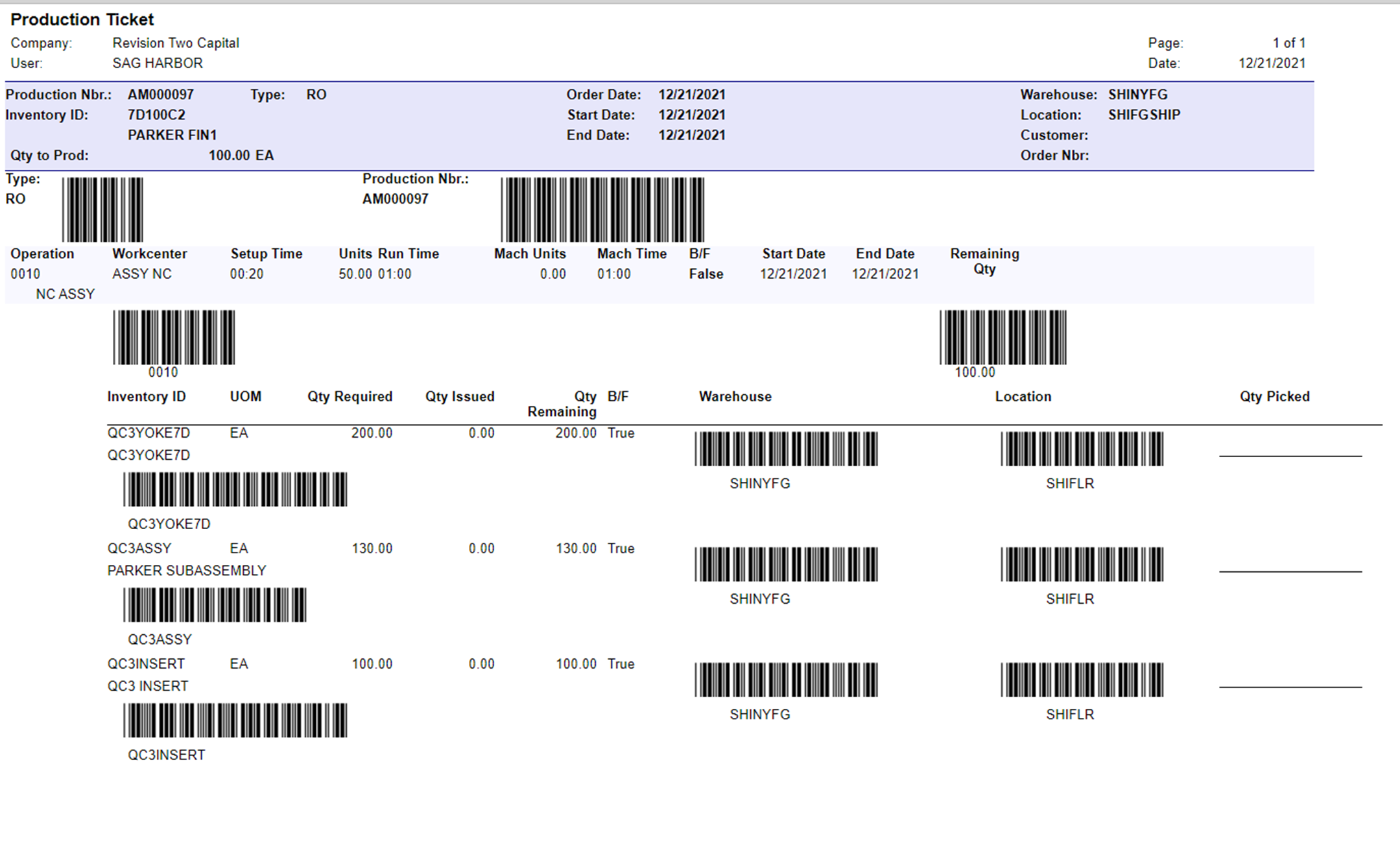

Have you explored Phantoms in the manufacturing Module? In my opinion this would be the most similar to Legs.

Let me know if this helps or if you have questions about phantoms.

-Andre

Hi Andre,

i am glad you mentioned Phantoms, isn’t that where it is Phantom, the system automatically issued a subassembly/leg production ticket and using standard cost set in the “leg” bom? if so, how are we keep track of actual labor cost?

we are in an environment where we have shop floor employees scan in their labor time for every production ticket.

Zoey

Zoey,

A phantom is a material type option on BOM materials. Once a production order is created for an item that has a BOM with a phantom material type, the phantom material requirement disappears. The phantom’s own BOM materials are then inserted into the production order on the operation where the phantom resided. In addition, you can specify if only the phantom BOM material is inserted into the production order, or if its routings should be included before or after the operation where the phantom material resides.

Materials and operations inserted into a production order behave the same as other materials and operations on a production order. You can set the items and operations to backflush, or clear the backflush checkbox and have employees issue material and or record labor.

Hope this helps,

-Andre

Thank you Andre, i am very interested into this:

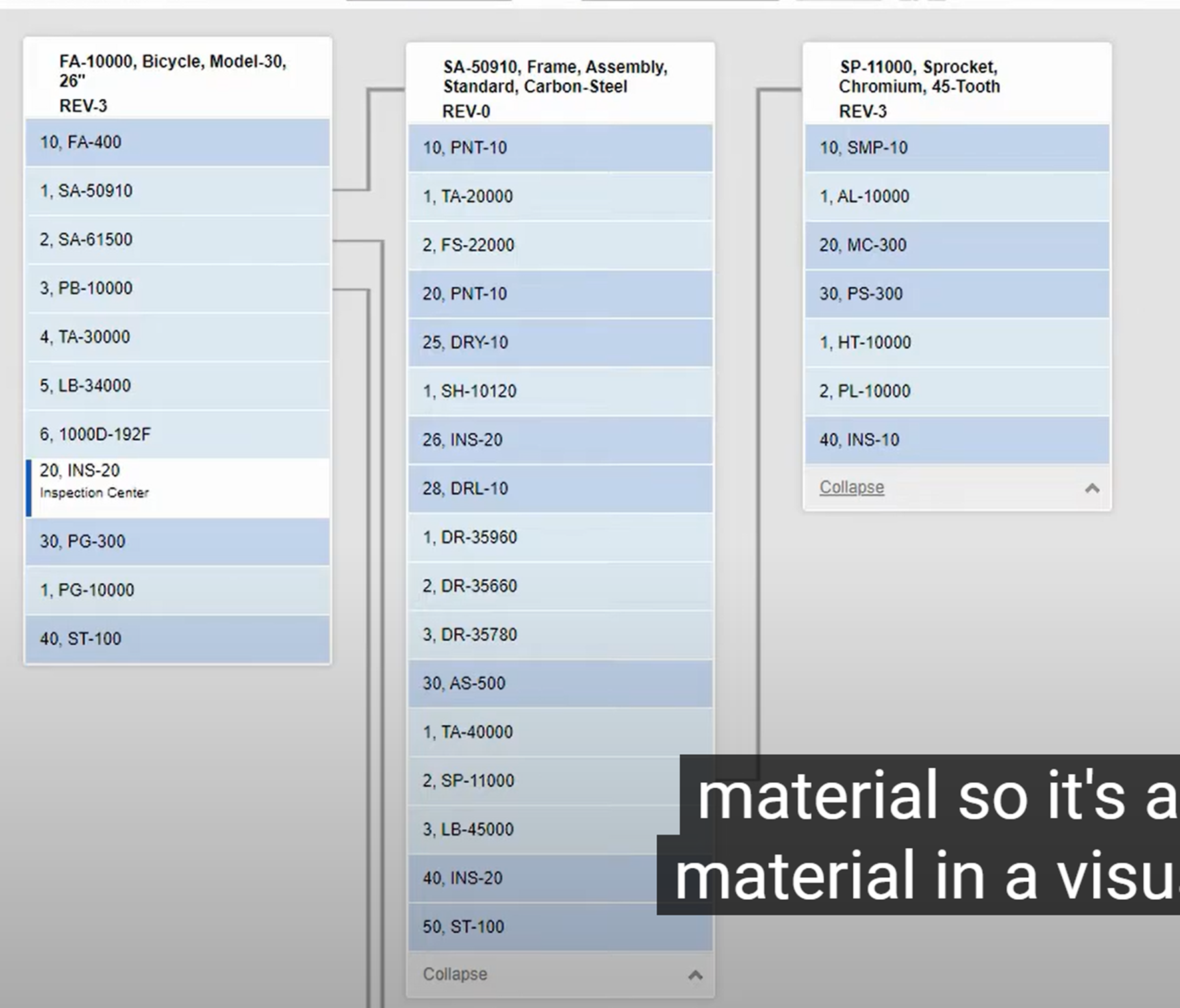

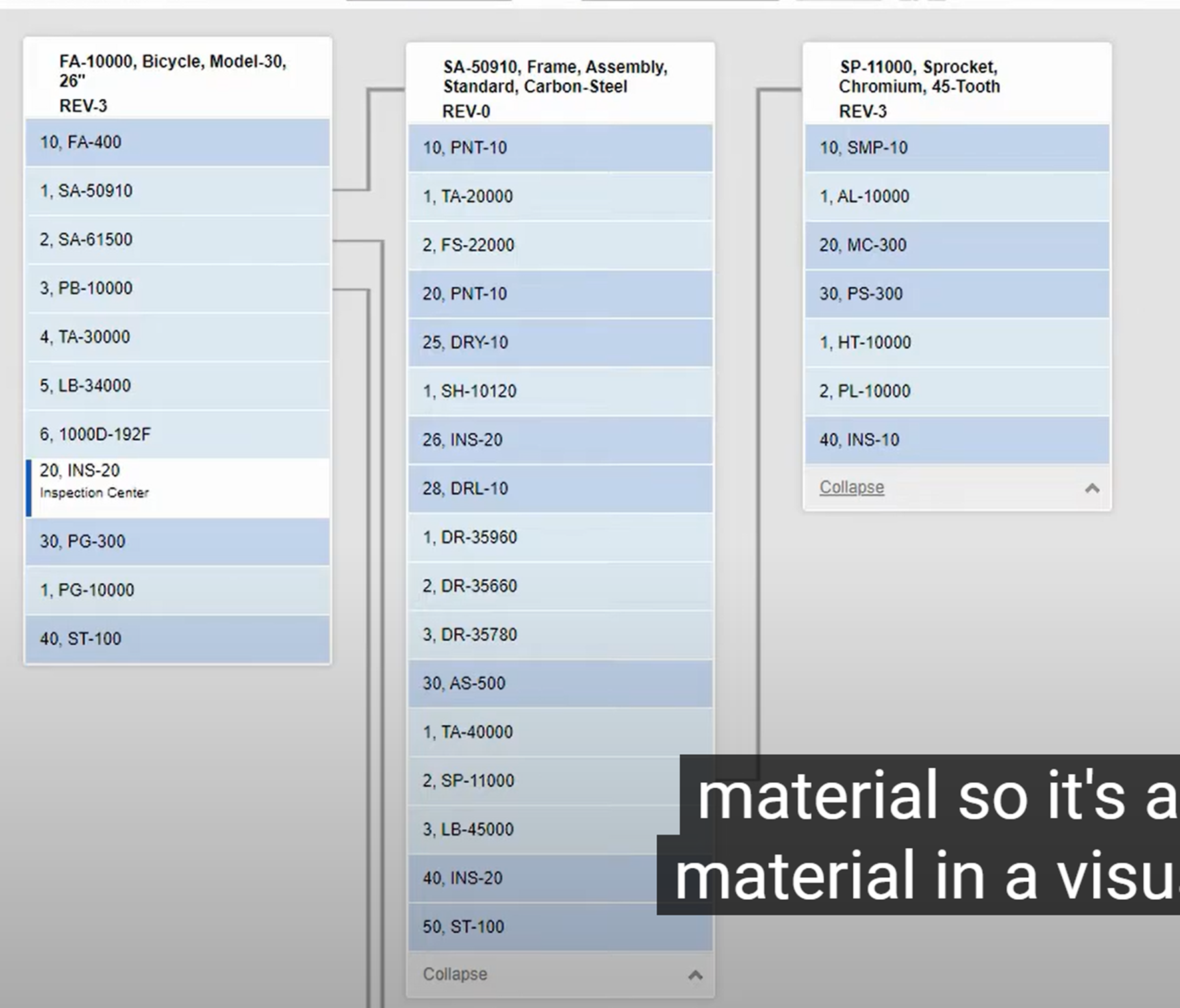

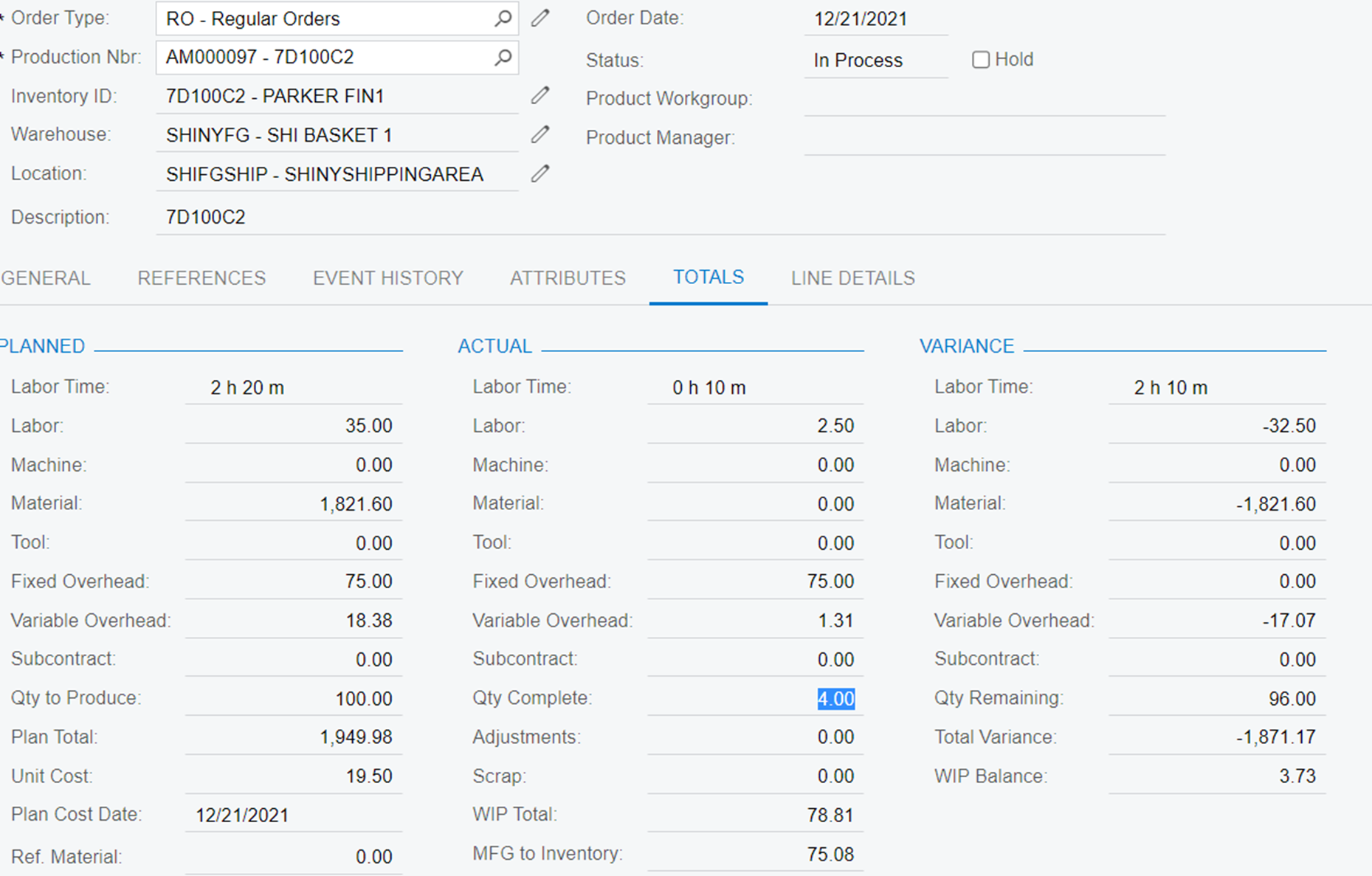

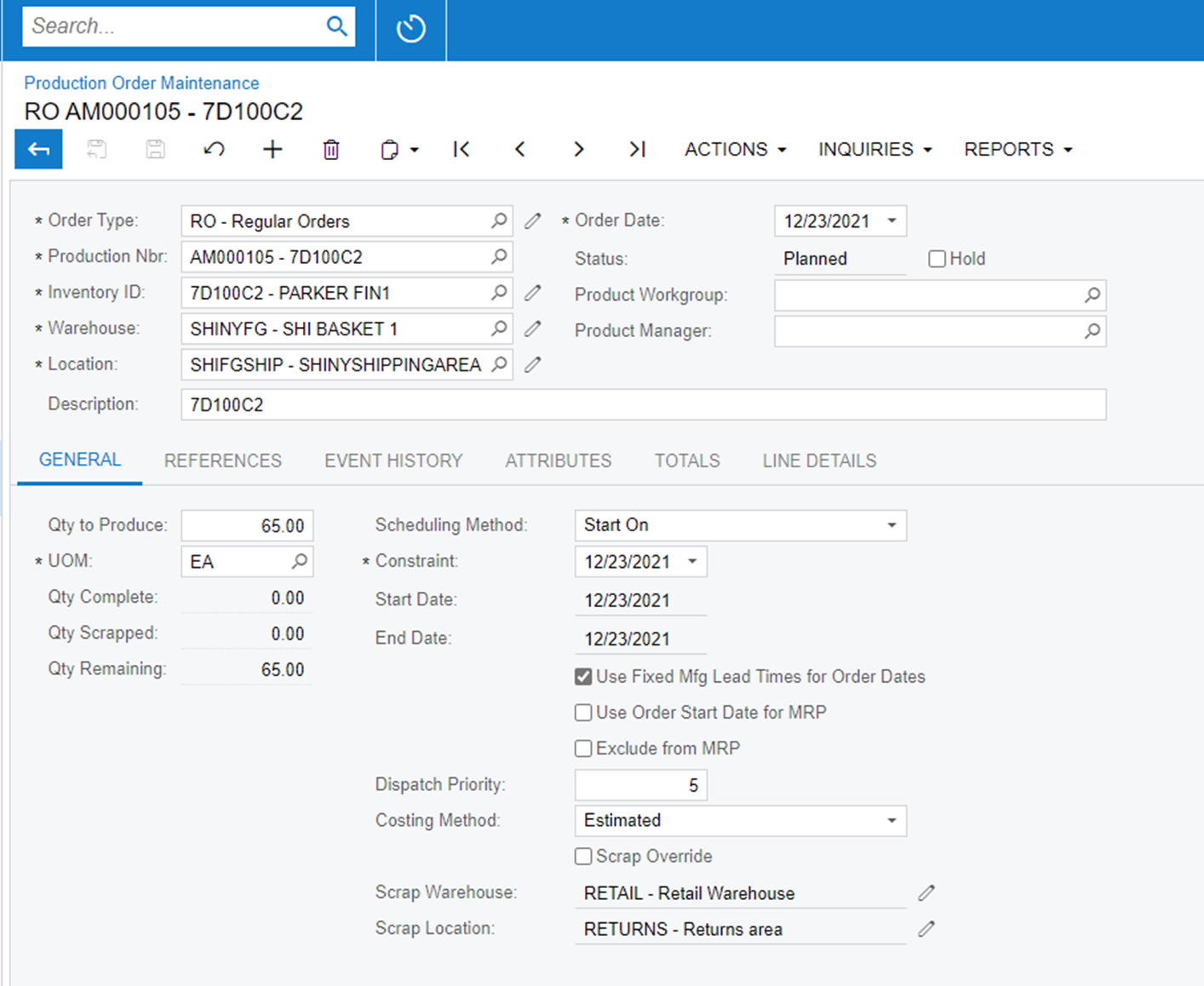

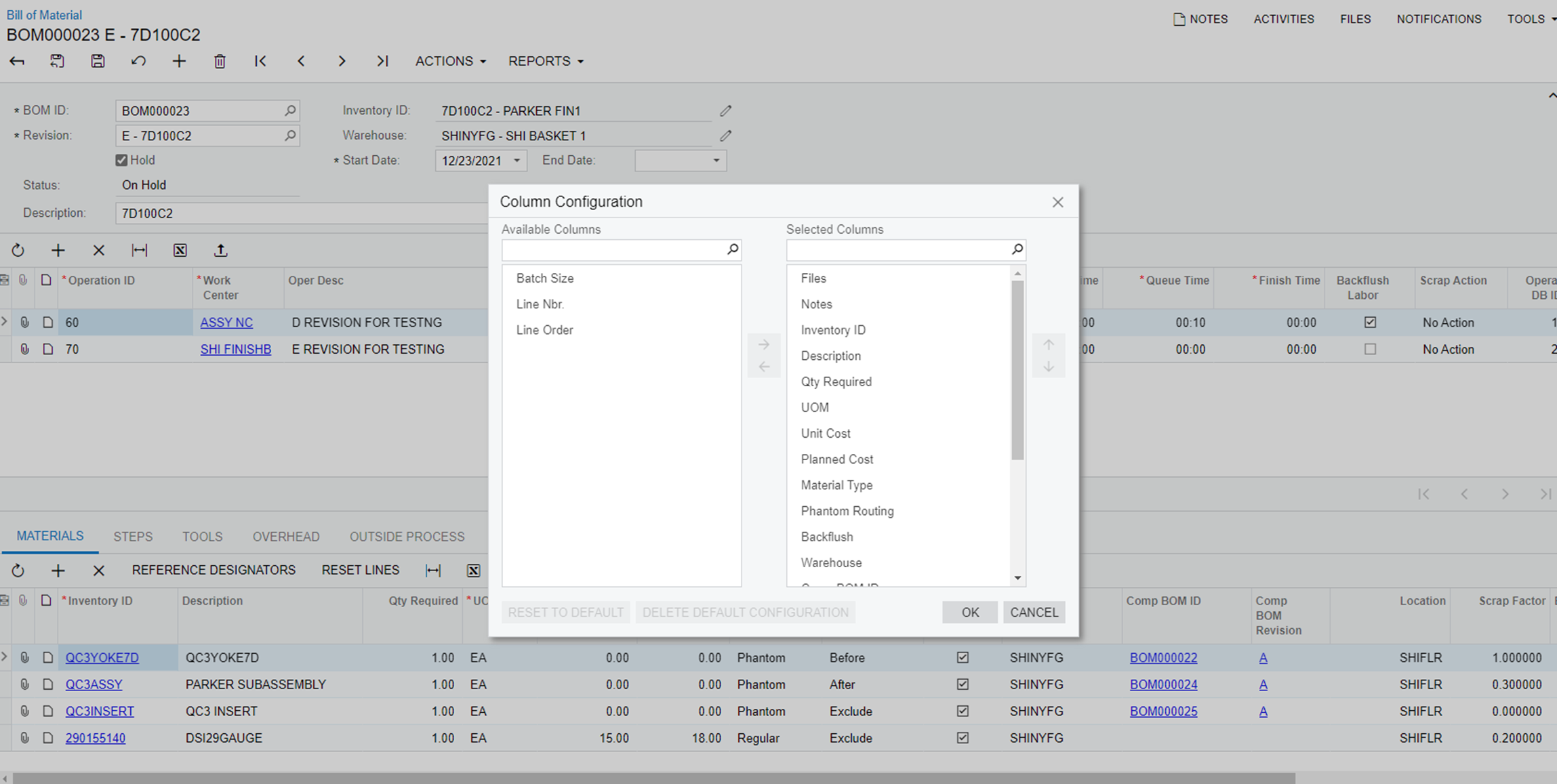

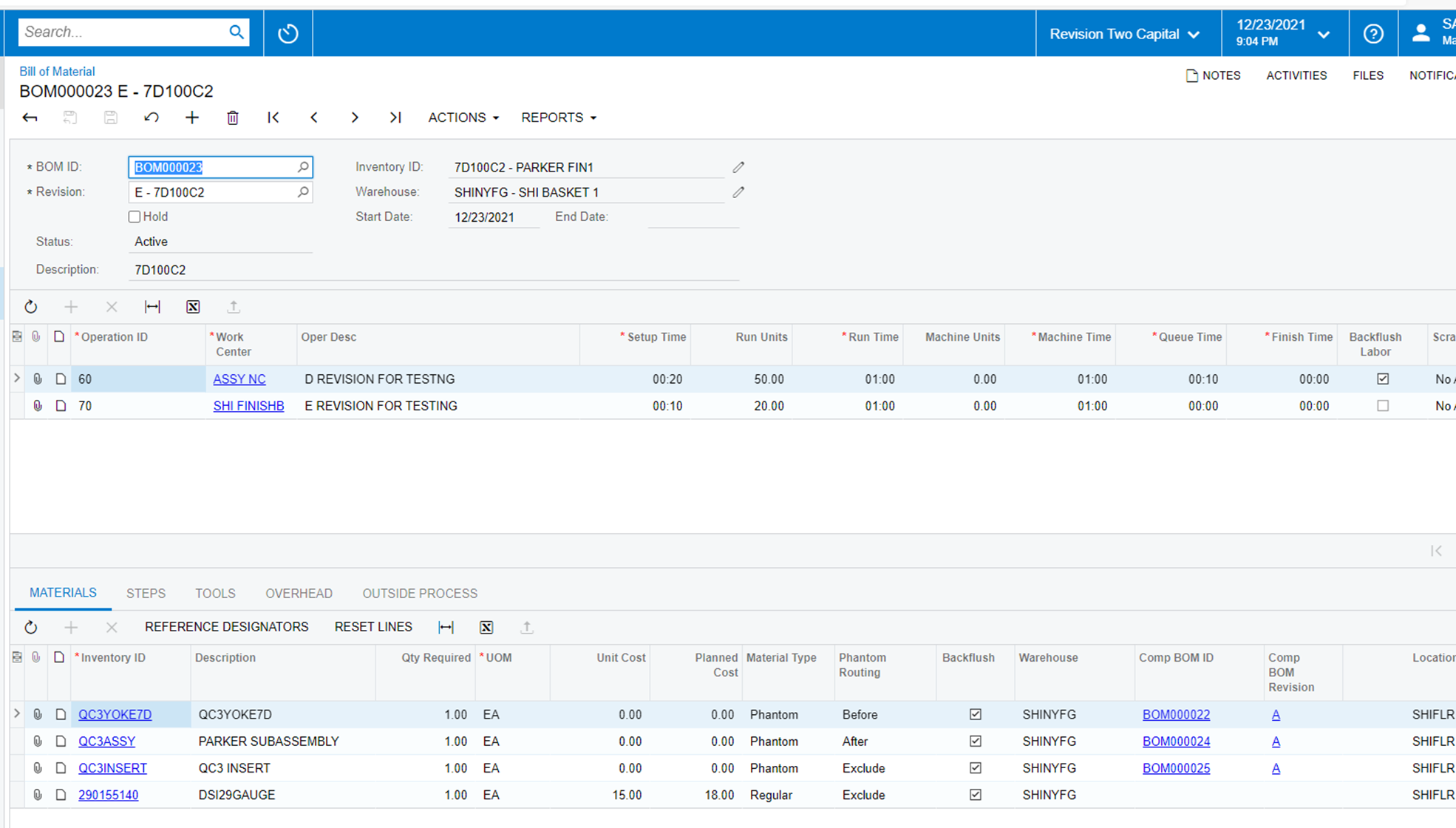

i create a bom see image 1 below: where BOM000023, OP10 has 3 subassembly, i set it up as phantom for all 3 of them set it as “beore”,”after”,”exclude”

and backflush all of 3 subassembly

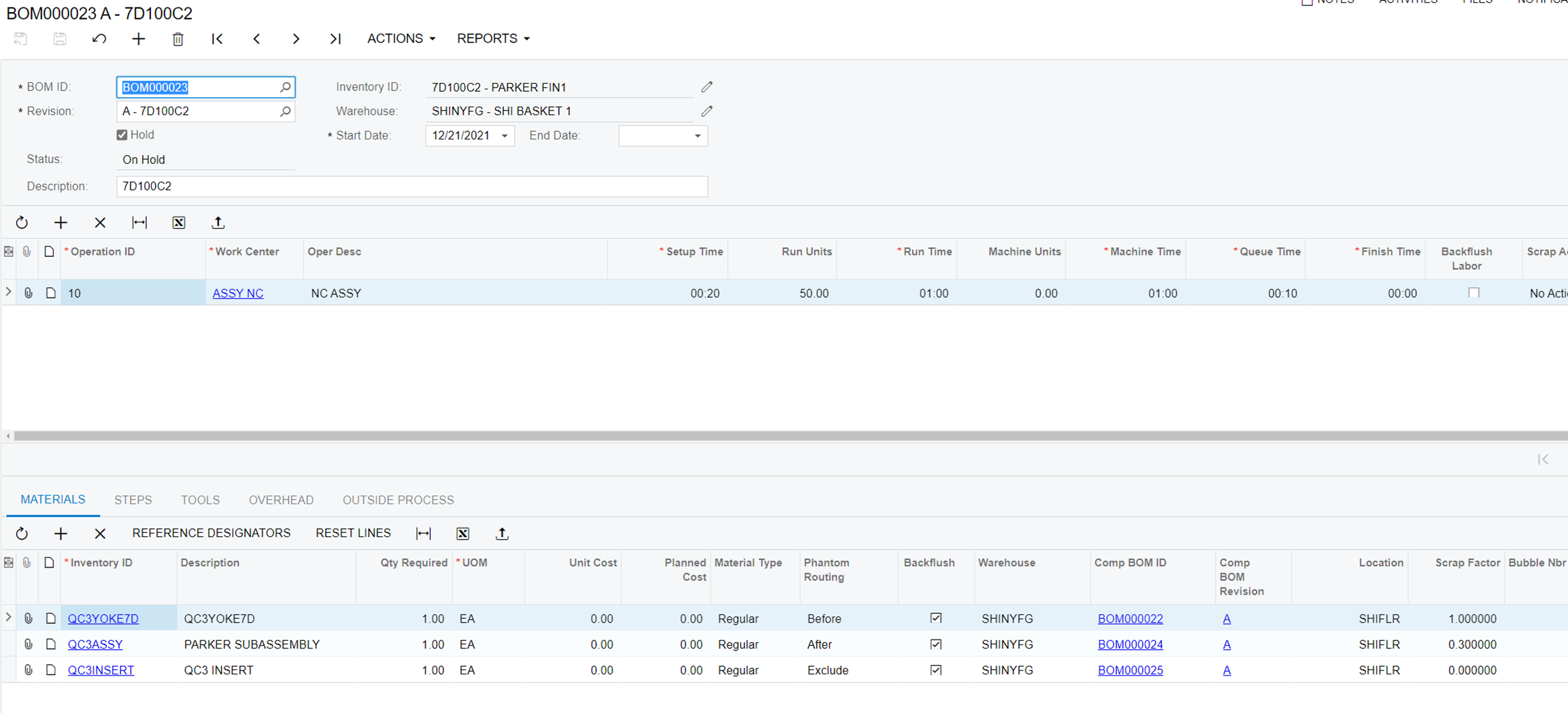

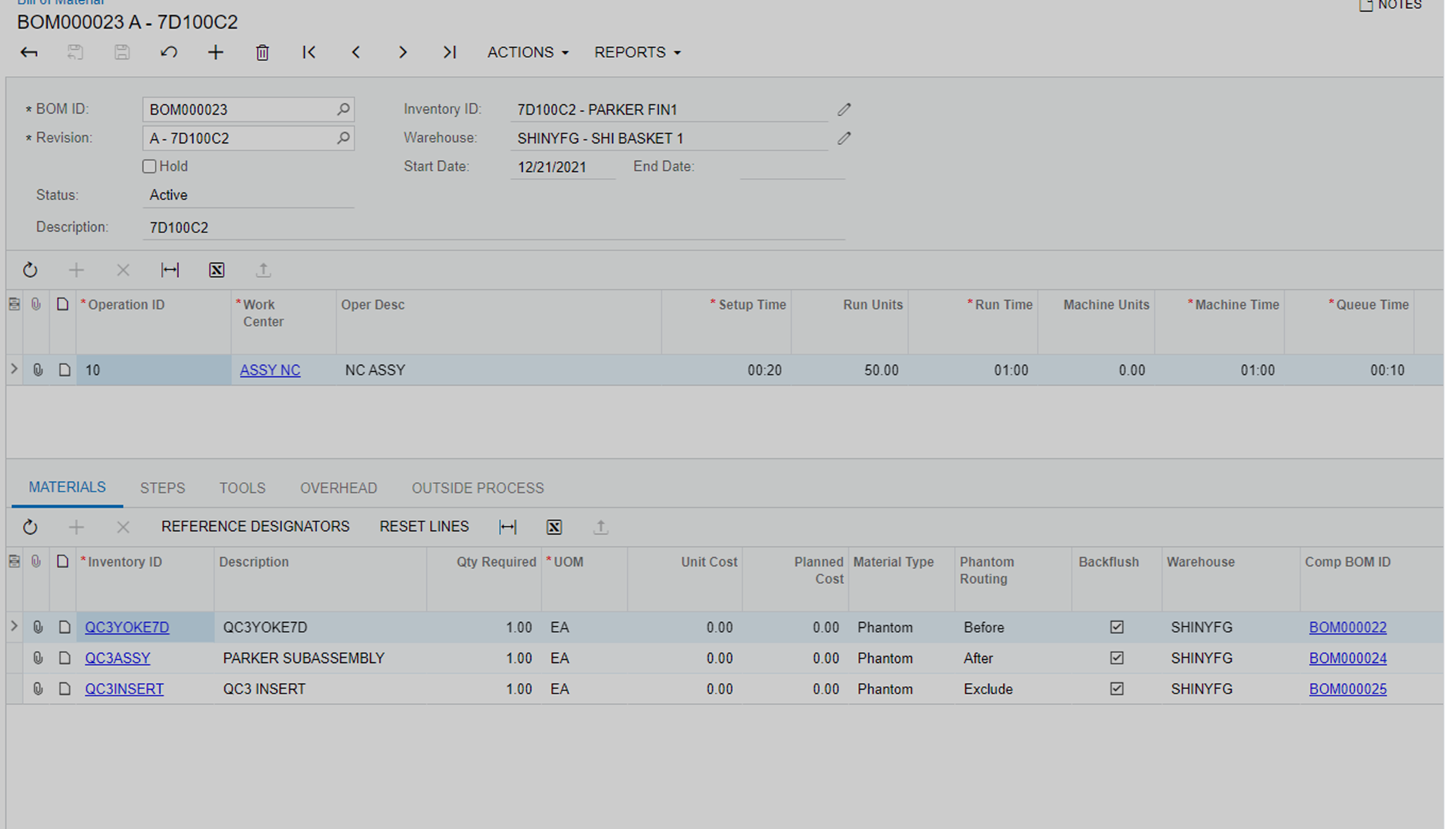

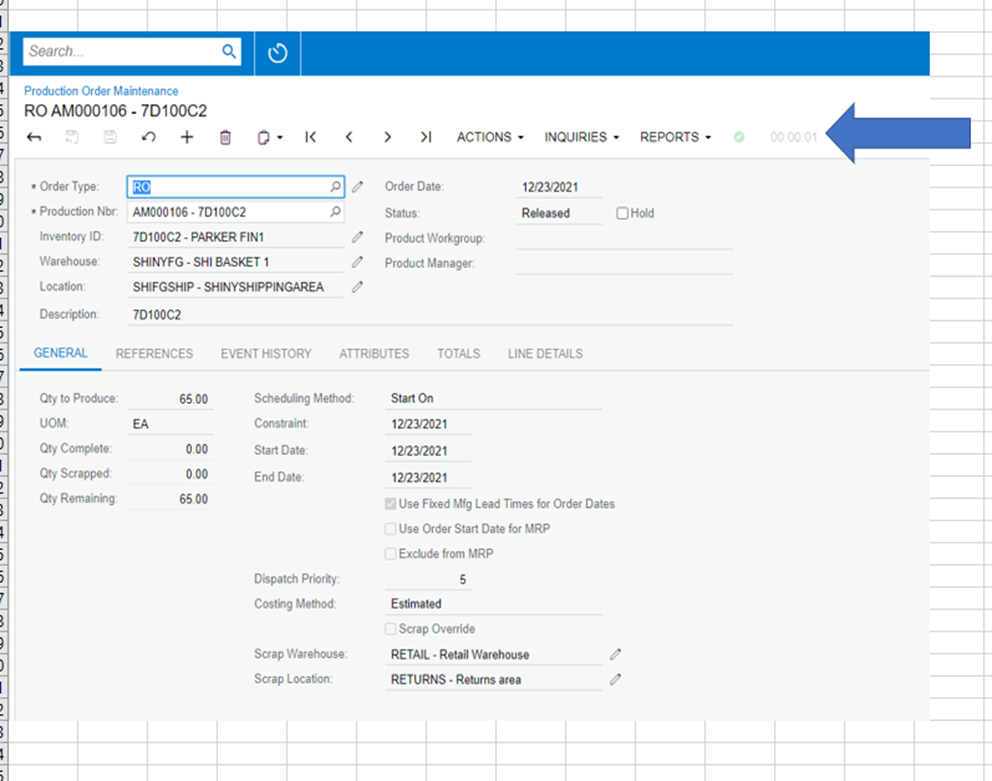

created a production ticket AM000097, see image 4,

operator finished 4 see image 3

so, i.e subassembly QC3YOKE7D, where phantom is set “before”, will the system automatically created a production ticket for this assembly when the main production ticket finished 4 qty?

sorry, it is lots of information to digest and we need to learn it

many thanks Zoey

Zoey,

The material type has to be set to Phantom, else the materials added are just regular materials.

See if that clears up the questions.

Hope this helps,

-Andre

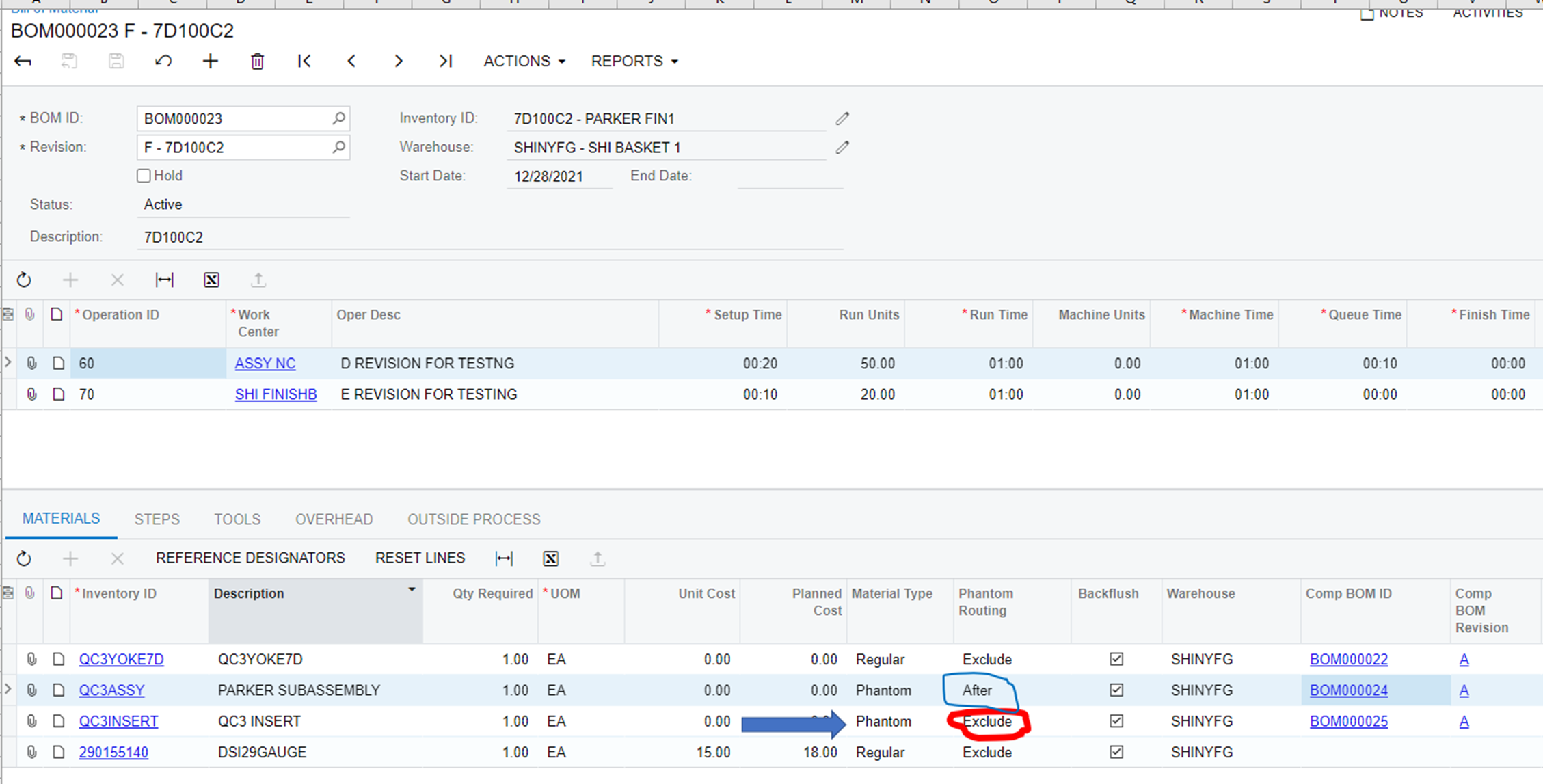

Yes it helps.. i see the difference in production ticket

Thank you!!!

questionS:

on the bom below, say QC3YOKED, phatom routing is set “before”, does this mean this subassembly is needed before the main op 10 (work center ASSY NC)? If so, then”EXLUDE” Meaning?

i will ask next question next.

-z

hi Andre or anyone:

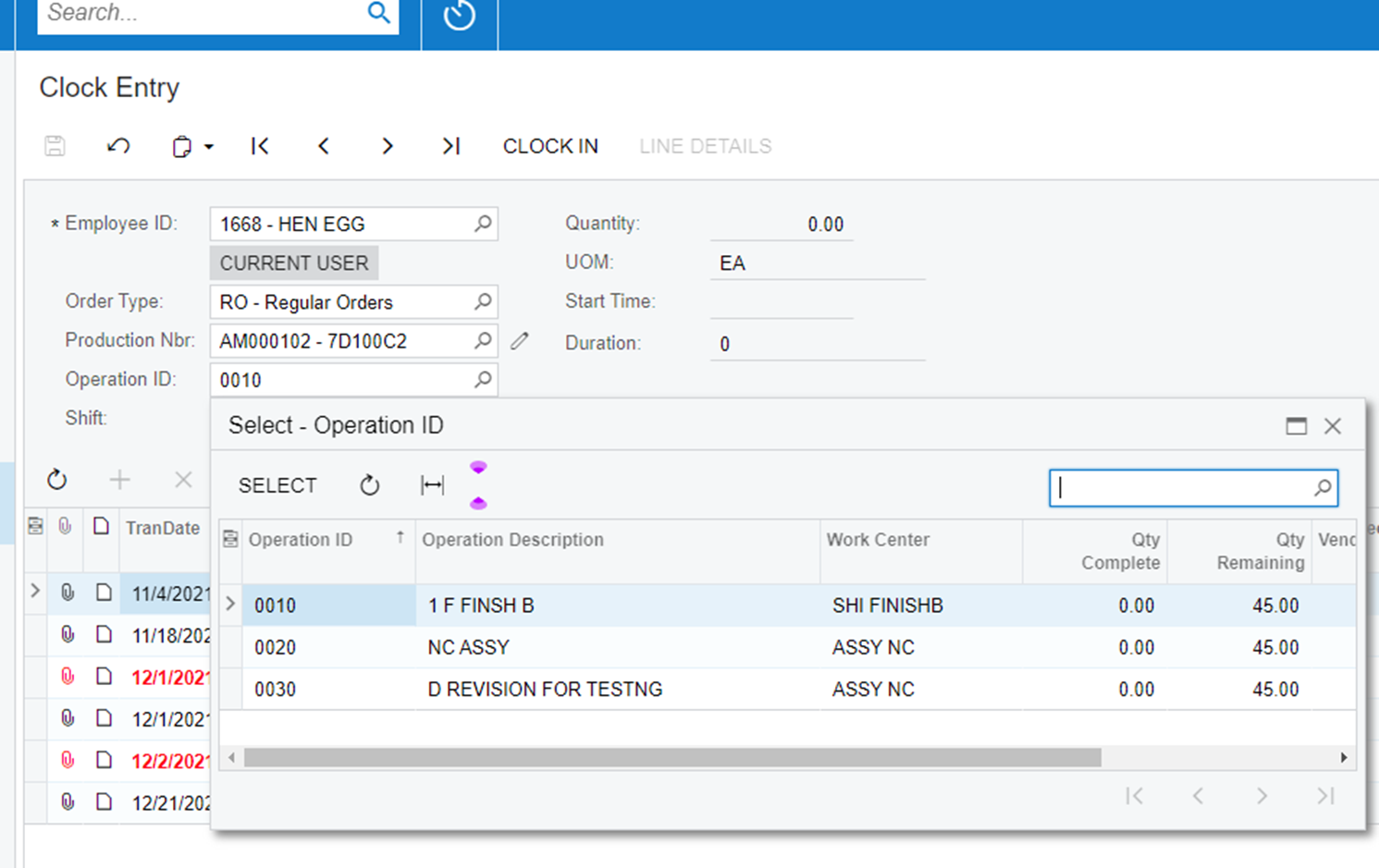

also, when i do a clock entry does not allow the floor labor to select the main operation ID..

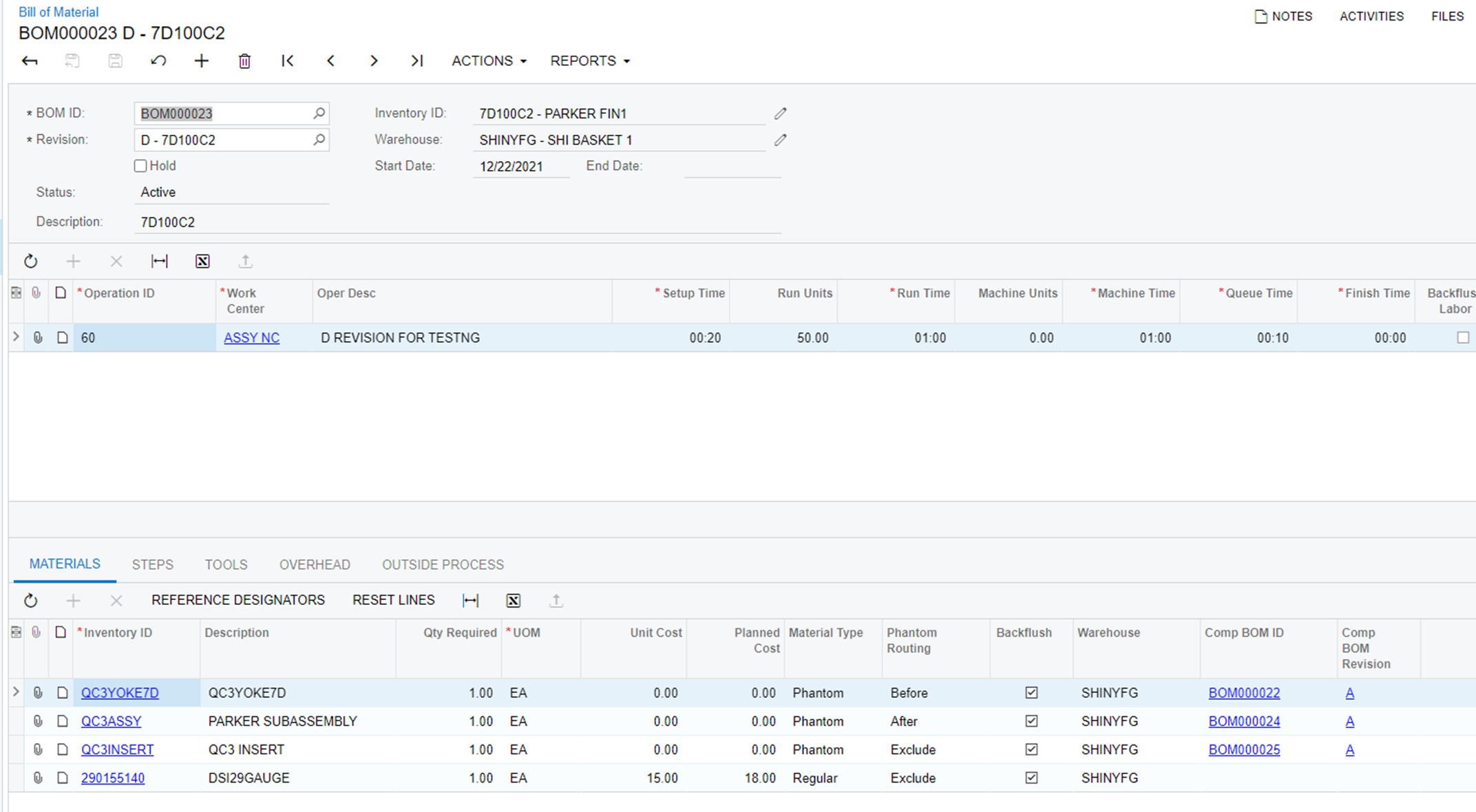

below image 1 is the BOM with op id as “60”

image 2 is the window where i am doing a clock entry, but op 60 is not an option.

where selections are available is limited to phantom ops only listed as “material”

many thanks

Zoey

The BOM operation numbers will renumber on the production order, so your operation 60 is now operation 30, because you have the phantom bom operations added before. If you had your BOM operations labeled as 1, 2, 3, they would end up being 0010, 0020, 0030. If you have them 20, 36, 48, it would end up being 0010, 0020, 0030. Take a look at the operations for the BOMs listed in your subcomponents and see how many operations there are.

Another way to capture the costs directly associated would be to go into each production order, and generate the linked production orders. Then you would get individual production orders for each of the sub items.

thank you Jeremy,

i have been created more version, and did notice the ops are renumbered by itself….

do you have any further information on

“Another way to capture the costs directly associated would be to go into each production order, and generate the linked production orders. Then you would get individual production orders for each of the sub items.”

thank you

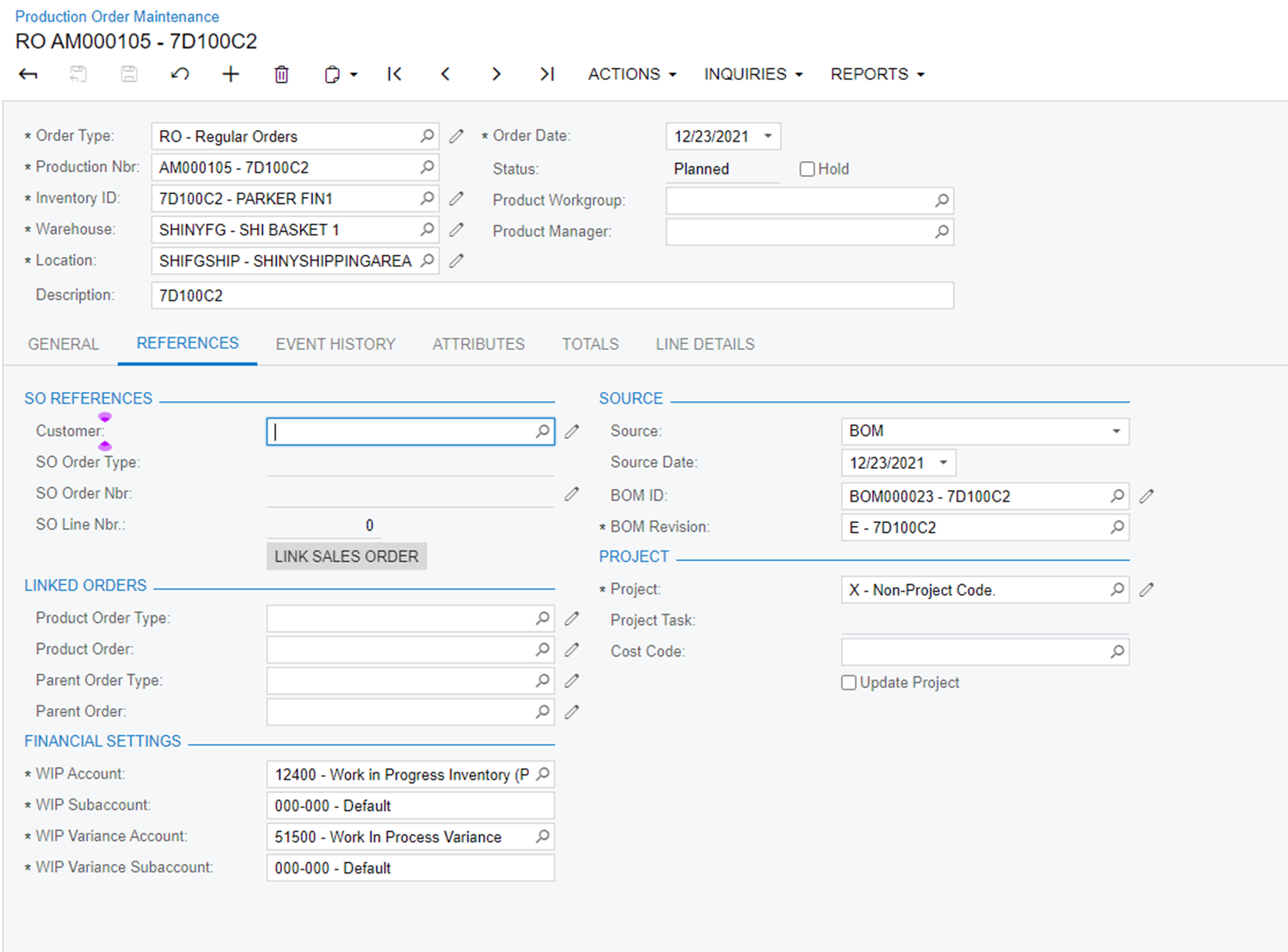

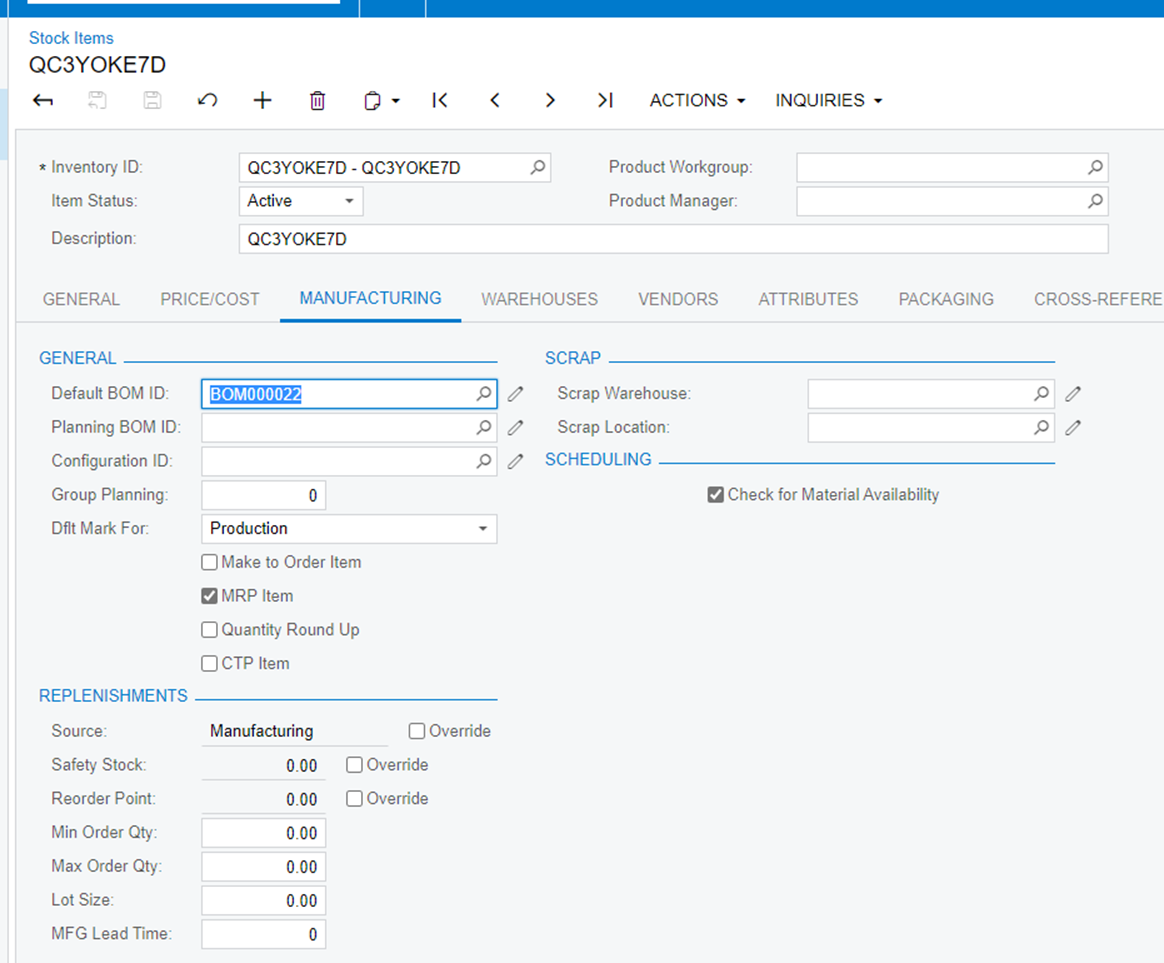

Once the production order is released for the top level item, go into actions and then Auto-Create Linked Orders, and it will generate individual production orders for each item that needs to be made. In order to do this, you need to have the Mark for Production Checkbox selected. When you go back into your production order maintenance screen, you will see that they are planned, and on the references tab of those orders, you will have the top level production order number as a link.

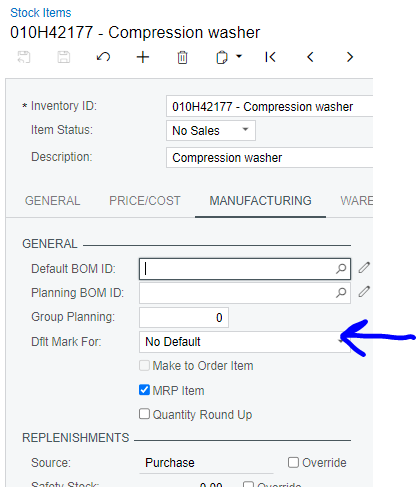

where i can find the box for “

you need to have the Mark for Production Checkbox selected. “

i dont have that field on bom level or production details..

My apologies, it is not on the BOM level, it is on the production details or on the actual item itself. If you open the Production Order, and go to details, you should have a Mark for PO and a Mark for Production Checkbox under the materials.

In the stock items screen, you can select the default to Mark for Production, or Mark for Purchase and this will be item specific. If it is a BOM, it should probably be defaulted to Mark for Production.

thank you, i made change to the “leg bom” to “mark to order”.. see image 1 and 2 below ( just 1 material’s bom set it to “production” for testing), and on main production, auto create linked order.( see image 3 below)

but i can;t find the new production order( or the subassembly production order) for the phamtom part though? is the subassembly production order generated as a separate production order?

thank you

Zoey

If it is a phantom bom, it will not generate a new order, it will put the connected BOM in the same order. if it is not marked as phantom, it will create a second production order.

I SEE it now.. thank you

may i ask where for a material, if phantom for material type is selected, phantom routing as “exclude”..

what does “exclude” mean?

also, “after” mean?

Enter your E-mail address. We'll send you an e-mail with instructions to reset your password.