My company is newer to Acumatica (since April 2020) and our old software (Everest) used to be able to handle transactions in this way very easily, here is a hypothetical scenario:

We are a car dealer and a customer is making a purchase of a new vehicle. The vehicle is in my inventory as a whole unit. The customer wants to upgrade the wheels on the vehicle, so we need to swap them out. We take 4 wheels out of our stock and install them on the vehicle then restock into inventory the 4 wheels that originally came on the vehicle. Then we sell the car. We can later sell the 4 original wheels to another customer.

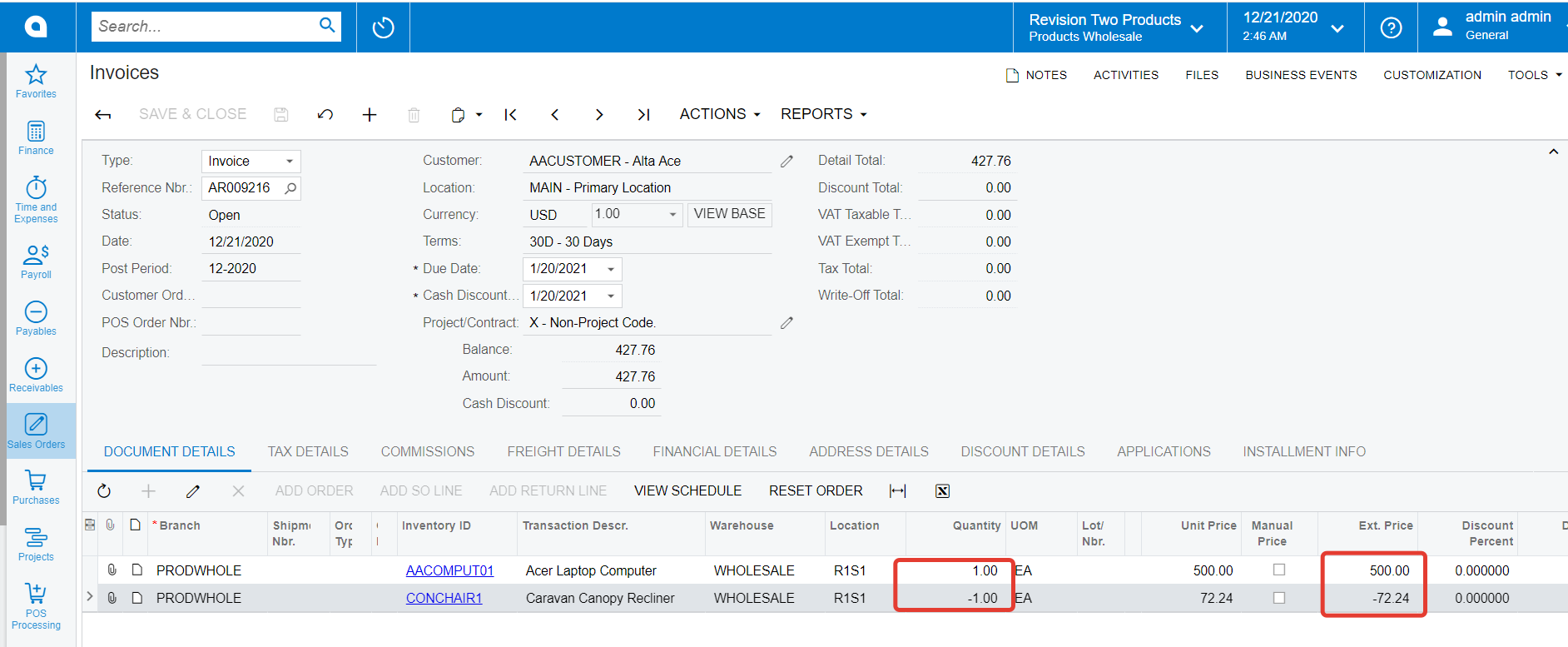

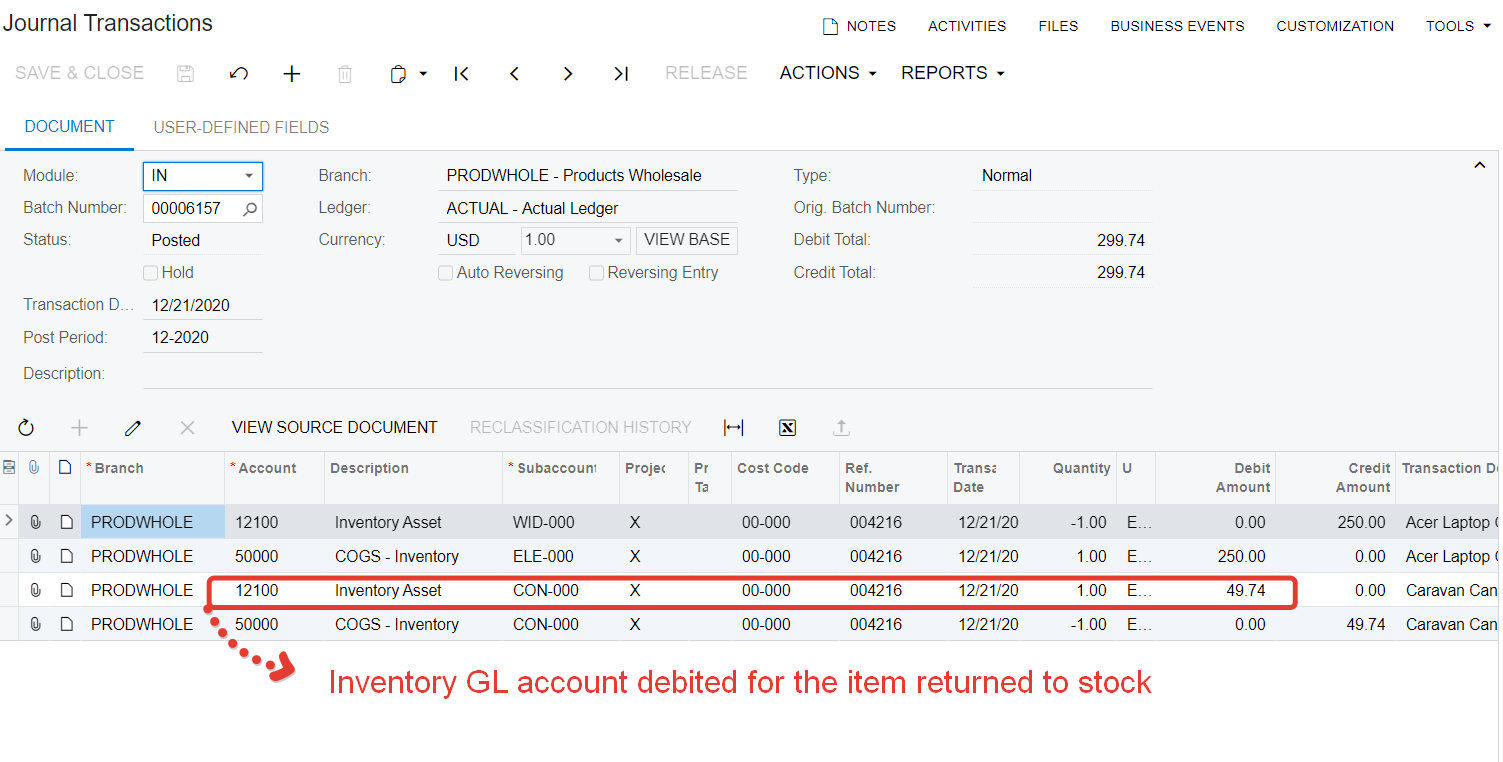

In Everest you can simply use a negative quantity (-4 wheels) on the sales order which in this case would bring 4 of the original wheels back into our inventory stock. Then put positive 4 of the new style wheels on the same sales order, effectively "swapping out" or "trading back" the wheels.

This type of transaction happens ALL THE TIME, multiple times daily here at my company and I have not found a good way to do it within Acumatica.

Thank you,

Matt Devine

Power Eagle USA

Best answer by vkumar

View original