Does anyone have any experience with scrapping a part number in a production while including the serial number? i tried to move a production order with a scrap of 1 and qty of zero but it won’t let me put a serial number in the field.

Hi Chris, no still haven’t figured it out. Currently if I need to, I just adjust the specific serial number out of stock.

So I use Serialized when received for 99% of my production and purchases of serial numbers. I have a part that is serialized and i want to scrap the part to get it into the cost of the production order but also want to make sure the serial number associated with that part gets scrapped. I do not backflush any of my serialized parts in production because we like to dictate the proper serial numbers as we don’t do everything sequentially.

I agree with you however I do want to add a couple of comments. I think this could turn into an Acumatica Idea, let me know if you agree.

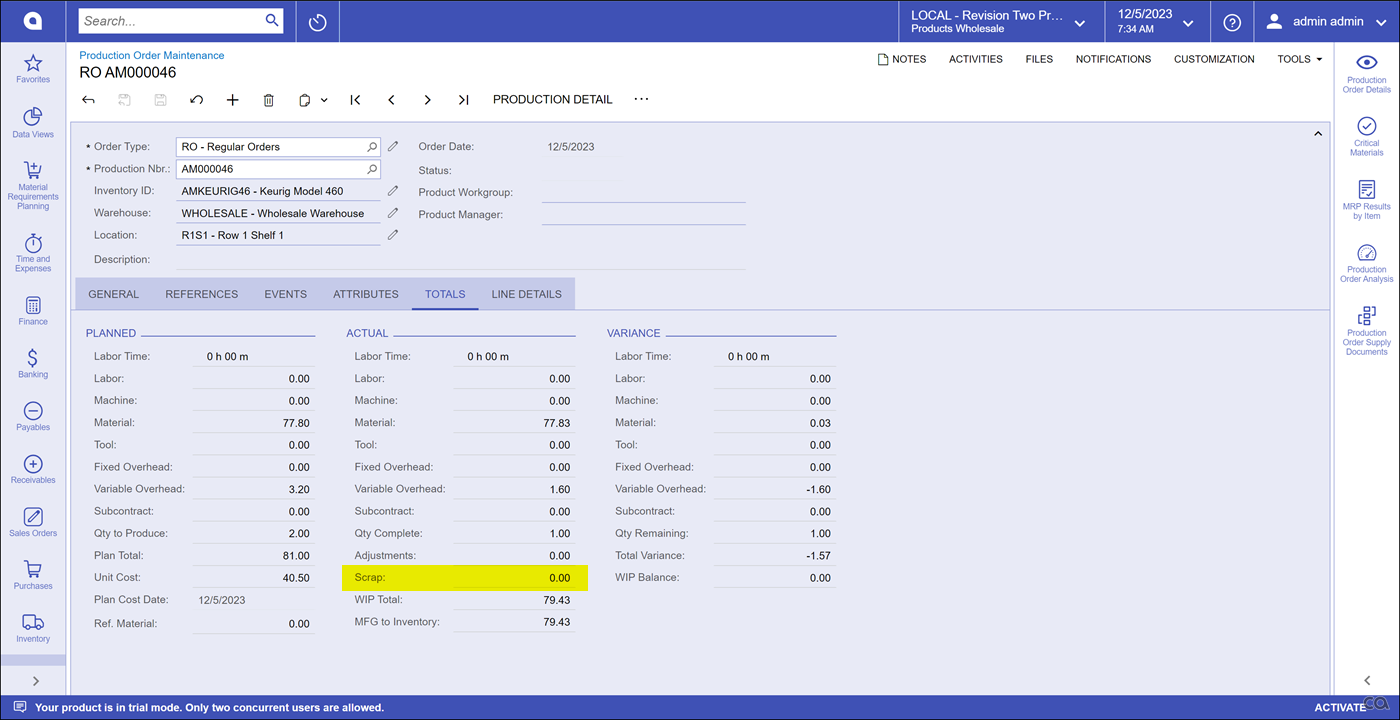

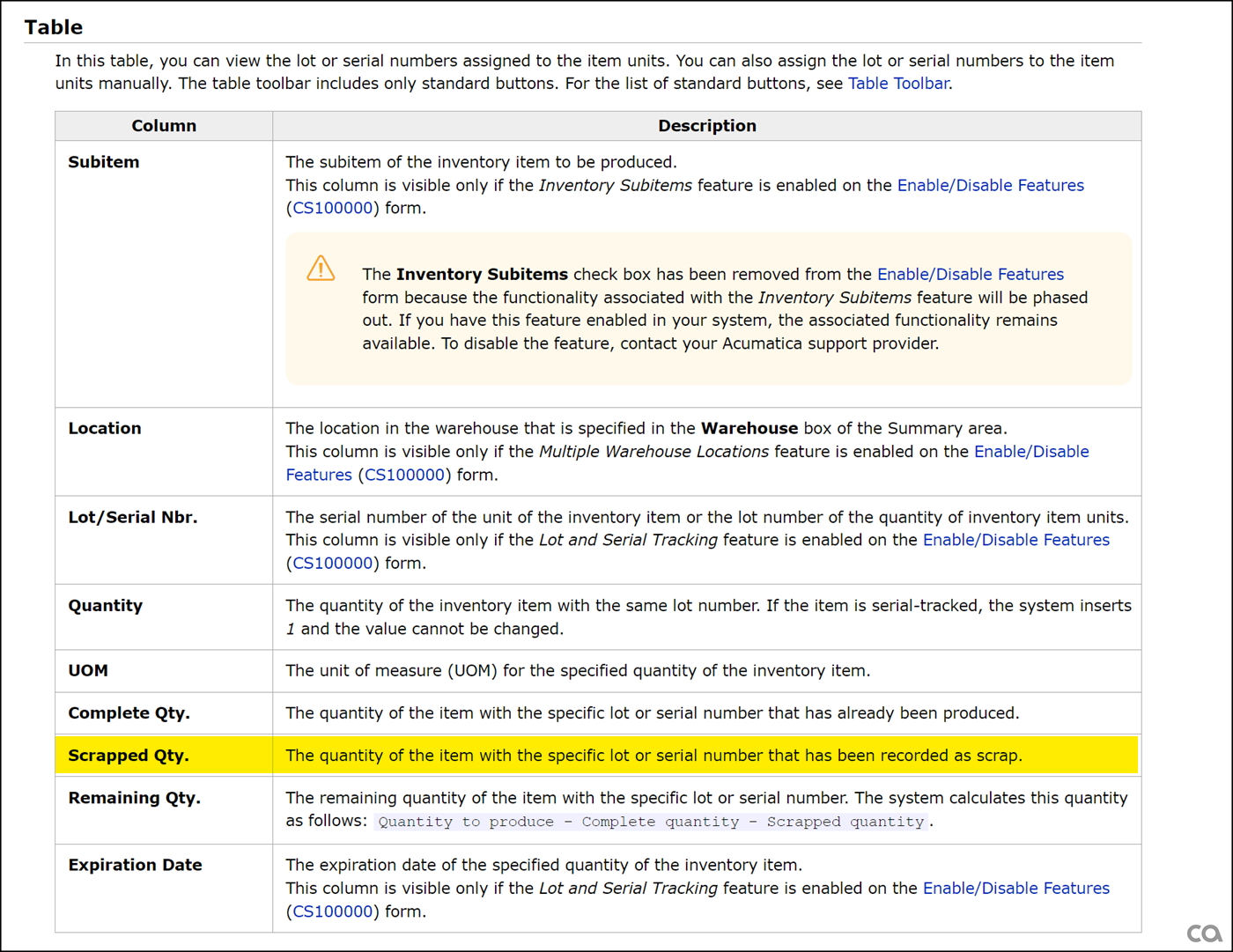

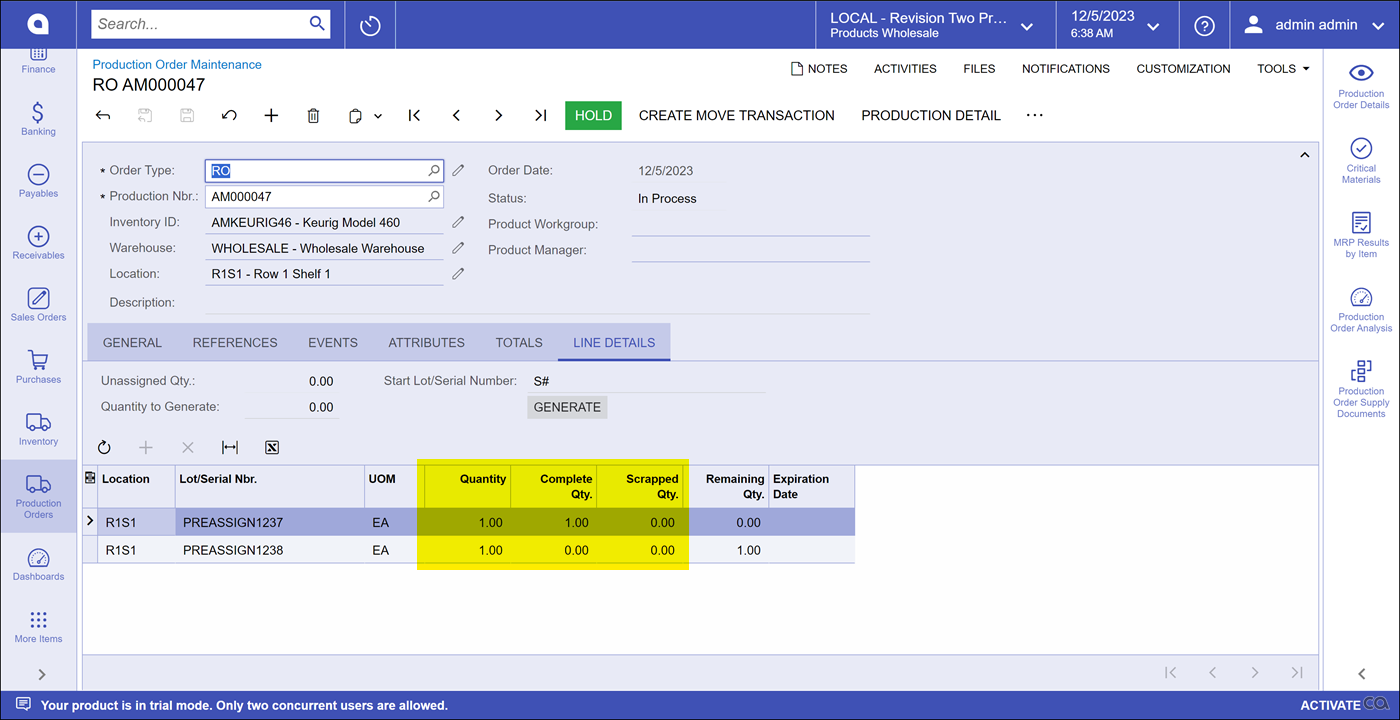

- WIP handling specific to a pre-assigned lot/serial number. In the case a pre-assigned lot/serial item has WIP cost associated with it (let’s say materials) how can we better accommodate the Cost of the Scrapped parent item.

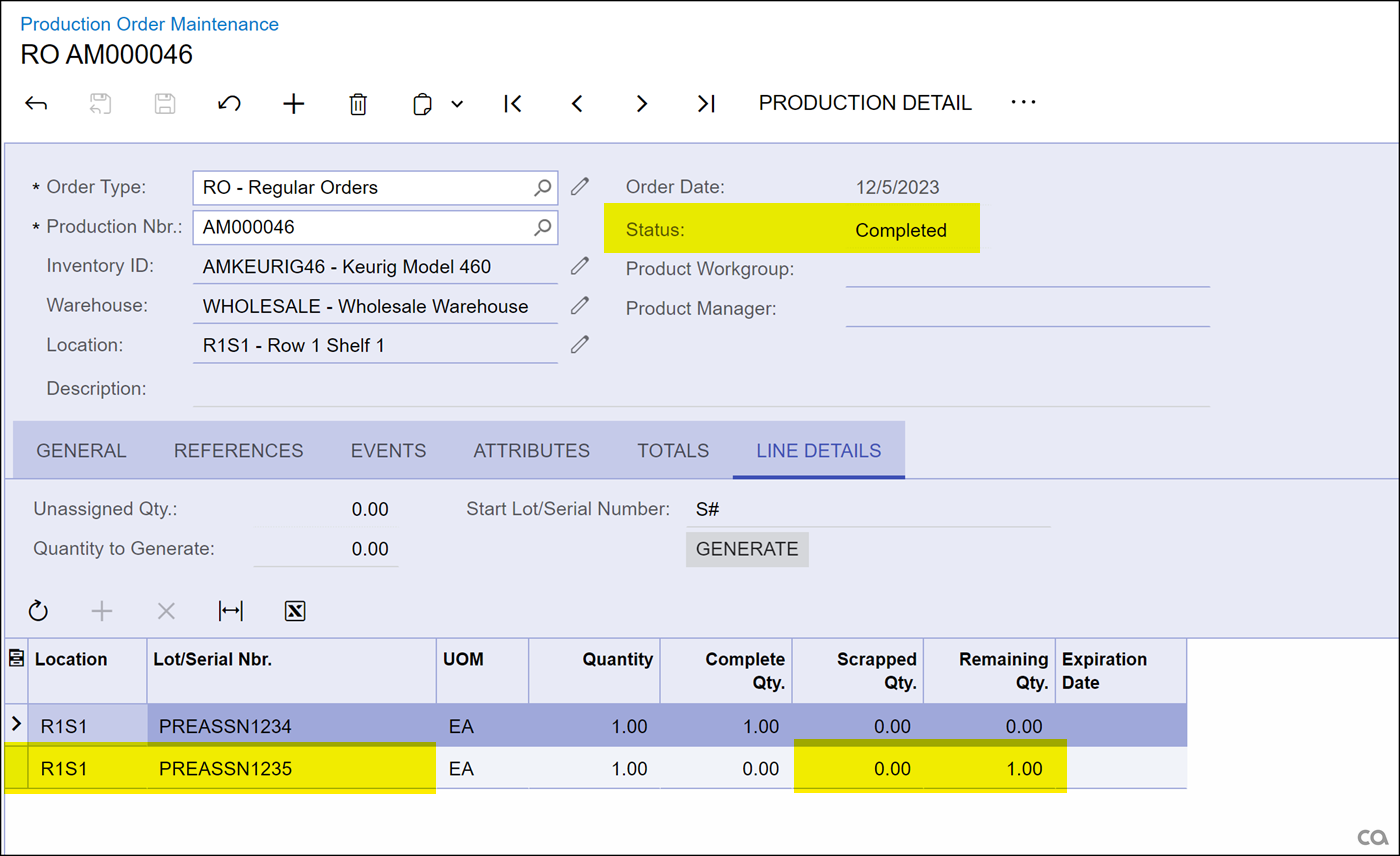

- On a completed Production Order how can we more accurately report line details to represent pre-assigned serial numbers which were not completed.

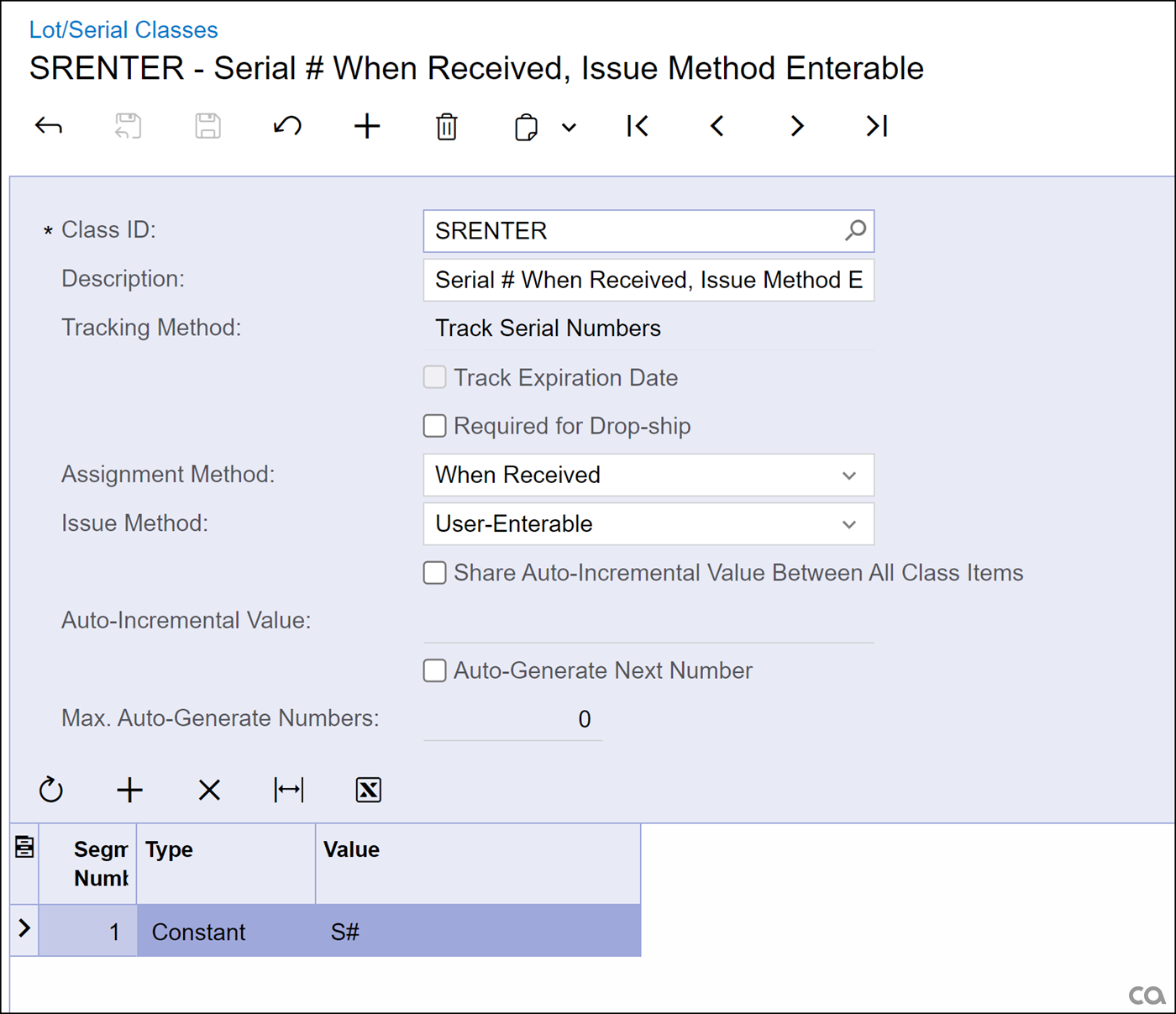

If you are assigning the serial # a time of receipt into inventory - then the scrap quantity would not have a serial # associated… right?

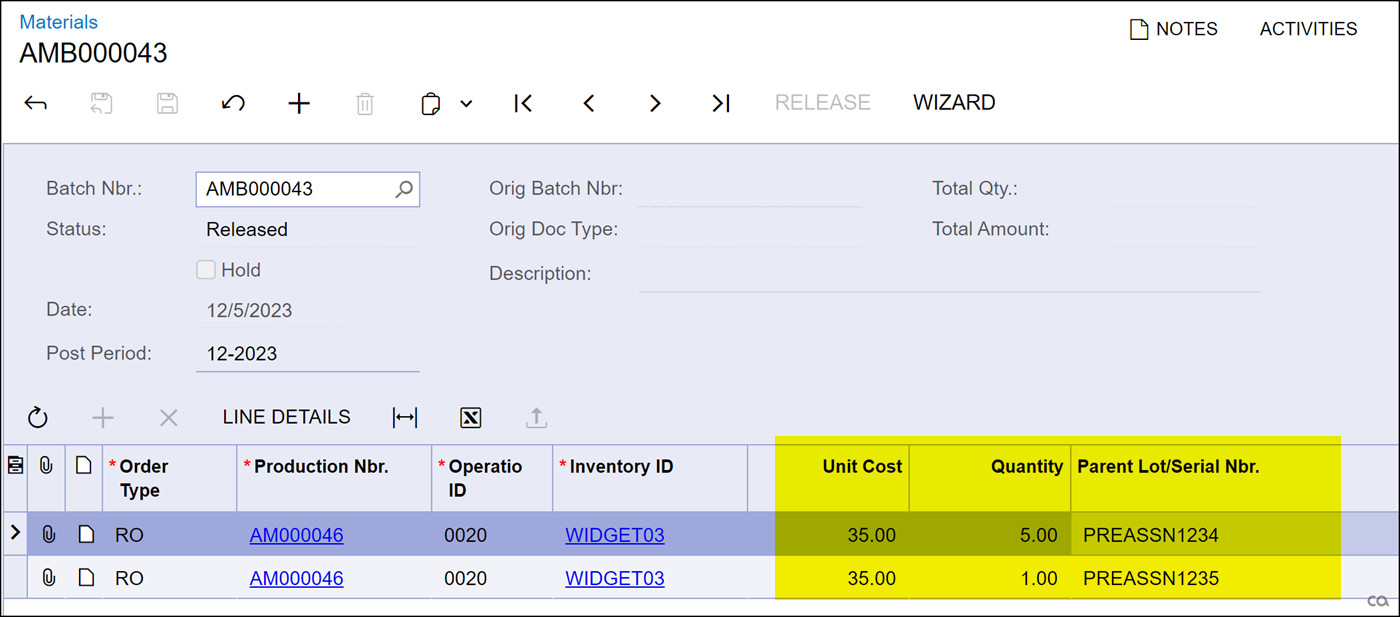

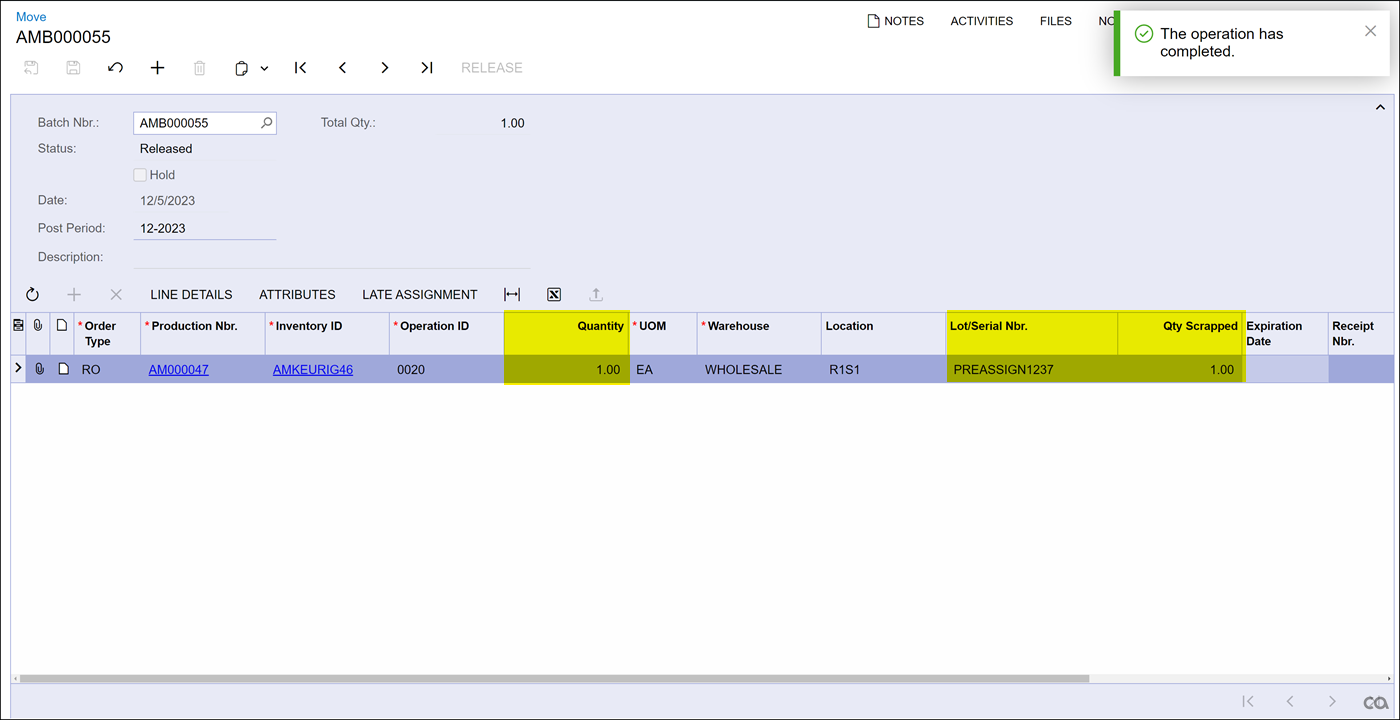

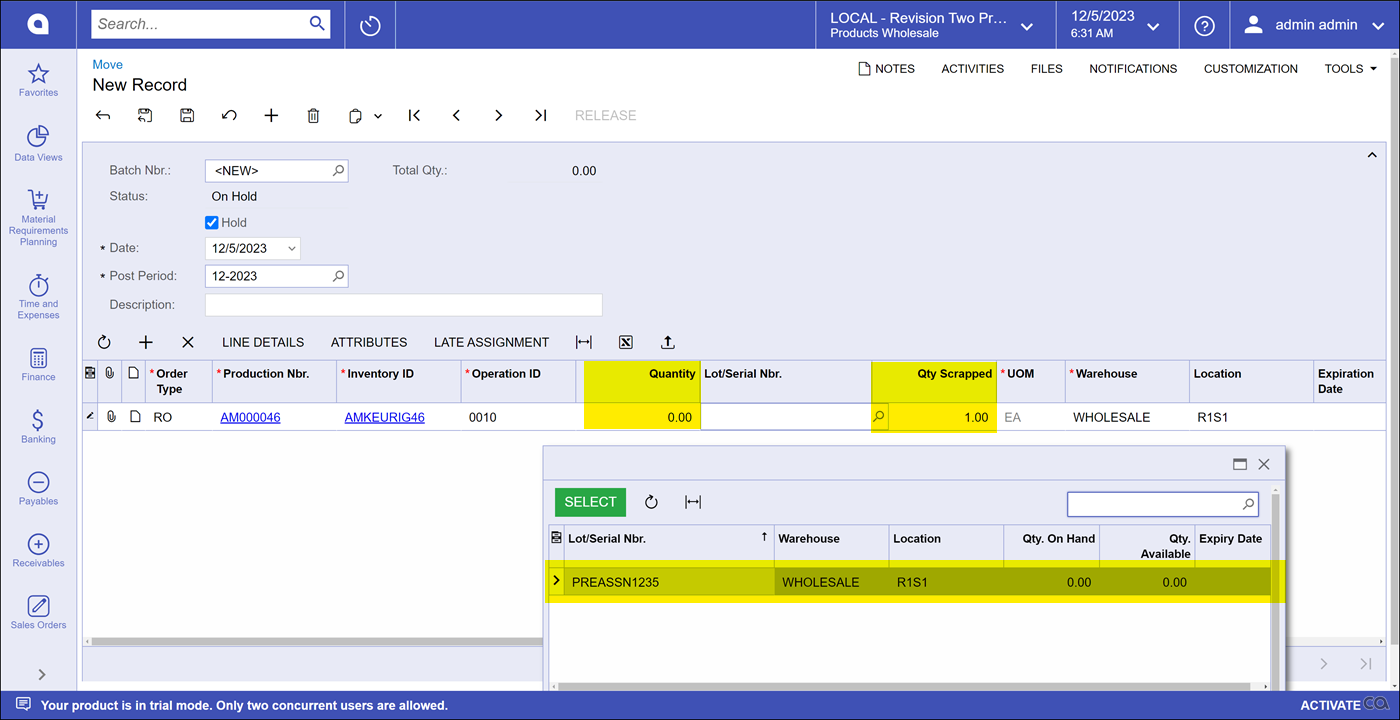

Here is what I was testing with,

Can you provide a screen shot of the Lot/Serial Class for you production item, please?

Reply

Enter your E-mail address. We'll send you an e-mail with instructions to reset your password.