Does anyone have an import template for multi level BOMs. I have BOMs that have multiple levels and include Outside processing. 2020 R2.

Best answer by kristianharianja

View originalDoes anyone have an import template for multi level BOMs. I have BOMs that have multiple levels and include Outside processing. 2020 R2.

Best answer by kristianharianja

View originalFreeman and I work together.

I’m back on this conversation thread because the BOM import that we were using for the past year doesn’t work since we upgraded to 2022R2 earlier this week.

For earlier versions of Acumatica.

The excel file structure is as follows.

BOM Header columns must have the data duplicated for every row of the BOM.

BOM Operation columns are only repeated for the first row of each operation.

BOM Material Rows are unique per row, so every row will be populated.

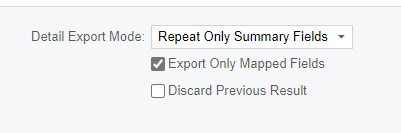

The above-mentioned structure is achieved by these settings on the export scenario header.

We only track operations and materials, so I’m not sure how you will need to set it up if you also have data in your BOMs for Steps, Tools, Overhead, and Outside Processes. You might need to upload that data with a separate import scenario.

We’ve been able to resolve our issue with importing BOMs. It seems there are various fields that are required on every line and you have to pay close attention to the demo Excel sheet as to which ones they are.

Do you have a sample of the structure of the template you used?

I have had major issues while trying to do a single bom upload using the acumatica supplied import scenario. You can do bom, but it does not always account for the multiple operations, materials, etc. I have never been able to use it out of the box in order to get it to work how I want it to.

I have built a few pretty robust ones to be used for both importing and updating the boms. The biggest issue comes down to the formatting of hours, since you need to conver the hh:mm into text fields using a formula in the excel document (=text(A2, “hh:mm”) to get the same format as acumatica.

Also, if you have multiple pieces of material you need to look at the @@Operation ID command, otherwise it will not bring in all of the material.

We’ve been able to resolve our issue with importing BOMs. It seems there are various fields that are required on every line and you have to pay close attention to the demo Excel sheet as to which ones they are.

Did either of you ever get a BOM import scenario working? We’re trying to use the standard Import Scenario and aren’t having much success.

We are able to import a BOM with a single operation and a single material, but not multiple operations or multiple materials.

We’ve had many cases where items come together to be sold as a single item on an SO. While each component or sub item has its own GL information assigned, as they should, when the item is sold it doesn’t seem to allocate the costs into the correct accounts based on the fine details of the sub items and only does so based on the GL information found at the top level, being the item shown on the SO.

Because these items are built on demand we’ve opted to utilize non-stock items and then, somehow, GL allocations have been assigned to the top level item that roughly represents all the fine GL details stored within all the sub items. not exactly an ideal way and not exactly precise.

thoughts?

Hi Evan,

You just need to bring those BOMs into spreadsheet template provided in Acumatica instance. You don’t need to specify their level because an assembly could be at any level depending on what parent items you manufacture. If an assembly has multiple active revisions you can specify the BOM ID and its revision ID in the Material line of its parent BOM to pick up the correct BOM when creating production order.

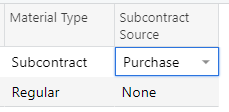

With regard to outside processing you could add a non-stock into the BOM and select type Subcontract in the Material Type and and source Purchase. This setup will separate cost bucket for the outside processing. Later in the process you can link the PO to production order.

With BOM, you can run Cost Roll to calculate the cost to manufacturing item that include/roll up the cost of subassembly. You can then use this as standard cost for your item.

Thank you for your response. It would nice to have someone to bounce ideas off of and get feedback. We started working group meetings; the next one scheduled for Friday. The major issue right now is to figure out incorporating outside processing costs within the BOM, linking the PO to purchase of the service on the production order and have it all roll up in the cost. Also, the company item standard costs are missing; another job to update. We are thinking about using non-stock items for the outside processing to include the cost on the Production orders; they want a non-stock item for each outside service (managing them becomes part of the process now). Also, I don’t have an idea how to incorporate the Assembly process unless we have a separate BOM for each finished good; which is going to make the number BOM to increase; managing them would be a full time job.

It is an interesting exercise. (I am a hired contractor so I want to leave them with most efficient and effective and easy to run Production process; not much support from the Supply Chain Manager). I think once we have an agreed on business production process for Assembly; the next battle is going getting the manager to reduce the number of BOMS, or getting them to set up generic Assembyly BOMs that can modified as needed and setting up the assembly process which is built based on inventory not on demaind MRP is the next process areas as well.

Let keep in touch. We can have phone conversation if you want to email. Which do you prefer?

Hope you are having a good day.

Evan, I’d love to hear more about this!

I suspect we will be entering into a similar situation in the next few months of our phased implementation of Acumatica. I’ll be the person that will be setting up the BOMs with the supporting steps and such. My initial thought was to build basic BOMs in Acumatica then augment them on the fly by leveraging the in house scheduling system I built, via the Acumatica API, to add in all the specific steps and such. It’s likely only a matter of time before it starts to get “entertaining” lol

So far the consensus is that it’s a very reasonable approach. This means all the “special” quarks of our internal systems won’t impact Acumatica itself because the BOMs in Acumatica will be more of the output or results of our internal system.

I’d be happy to connect with you and share stories and maybe even find an option that’s a little more promising for you and further refine our plans. ;-)

We didn’t figure it out. The data from the legacy system is complex. It does not have much in the way of backend flags or identiifiers (SQL) to note the BOMs within the BOM on the high and low levels. Also the manufacturing BOMs are not denoted differently from assembly except by operartions that are mixed. We imported some data in the test config (incorrectly) but good enough for Supply chain to test manufacturing and edit some for assembly. But importing into the production site is going to a battle. Our vendor is no help either. The company has BOMs going back 10 or so years; I am trying to reduce the number but losing the battle.

I am thinking we are going to do a manual entry for Assembly and import the Manufacturing. Or do two separate imports. The template we were given by the vendor was overly complex or simply; I still don’t know.

Any suggestions?

Thanks for letting me vent.

Enter your E-mail address. We'll send you an e-mail with instructions to reset your password.