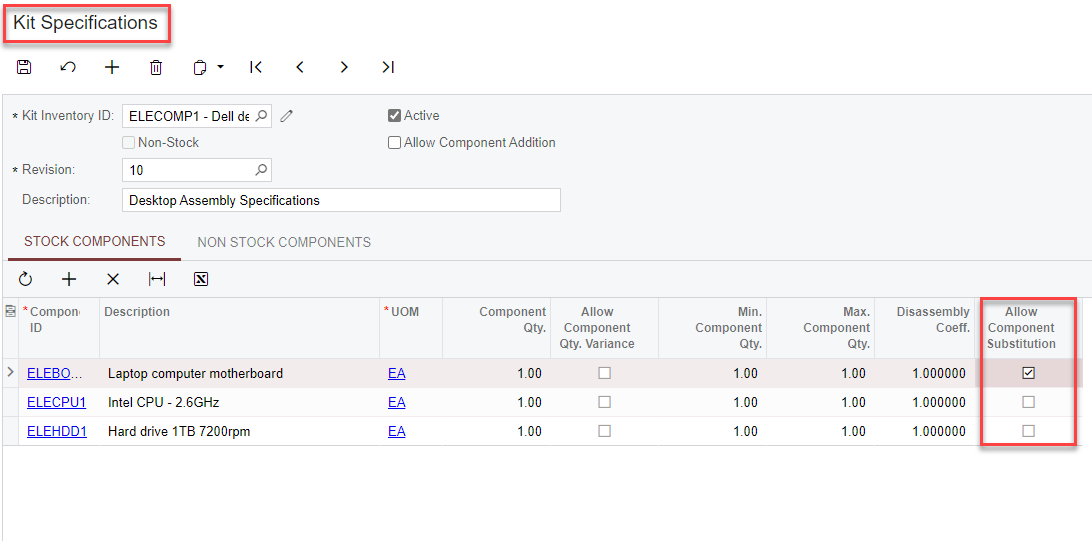

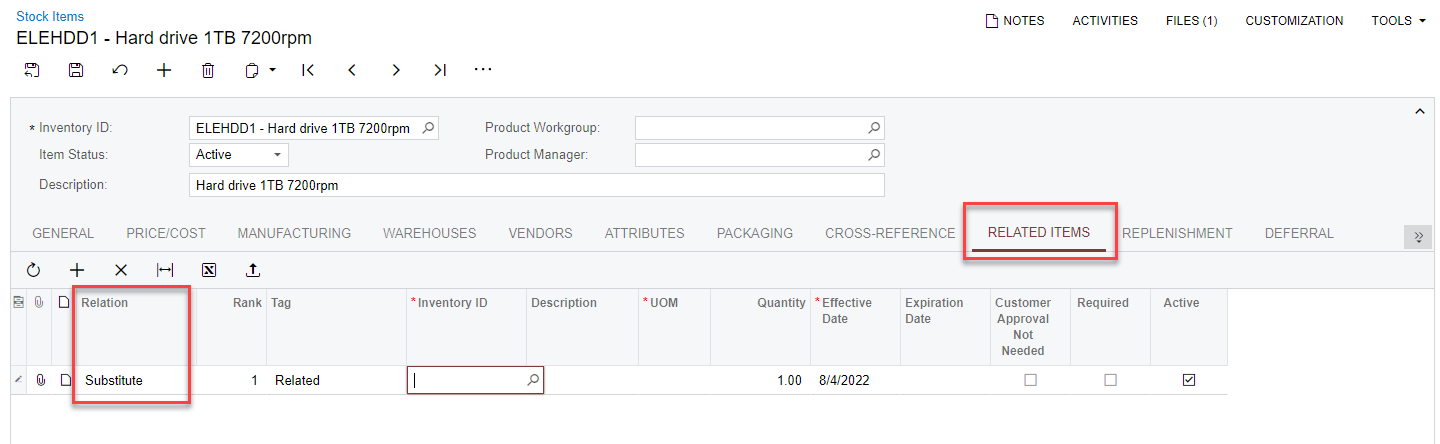

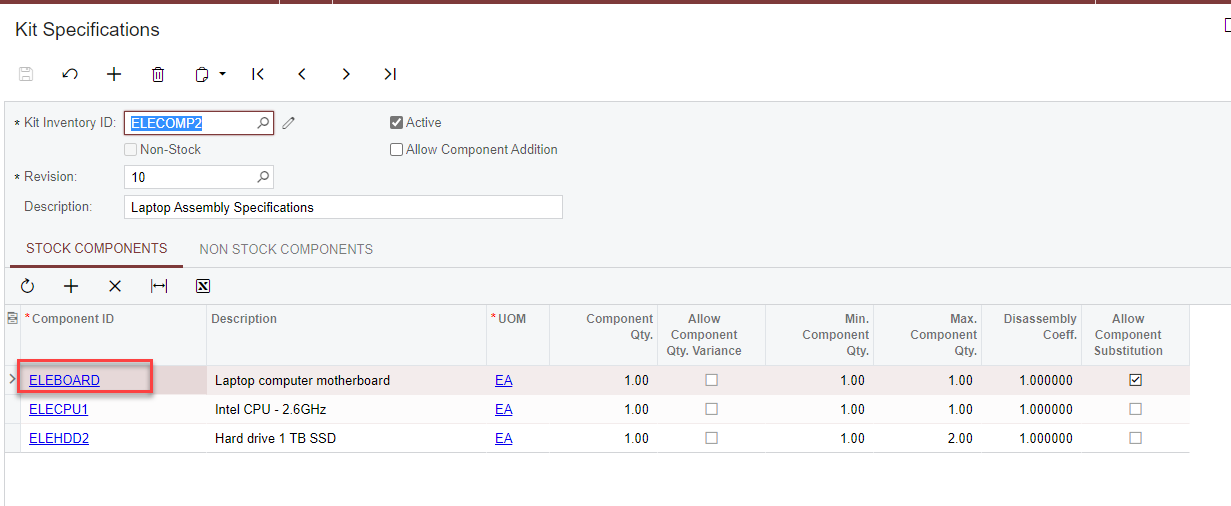

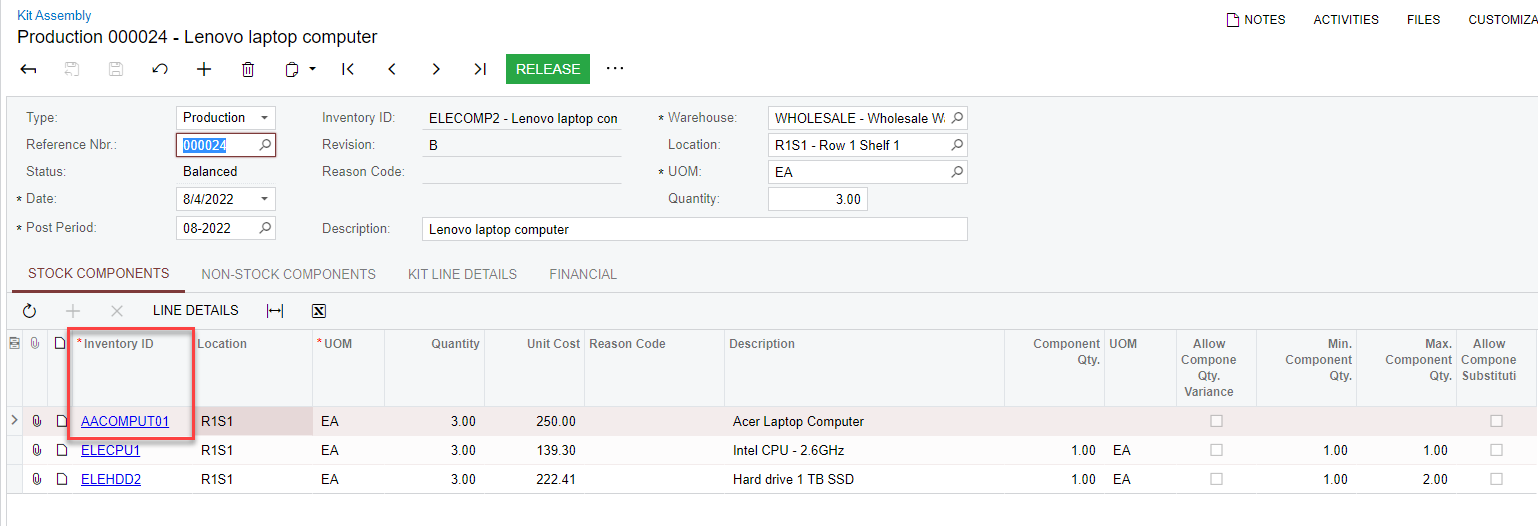

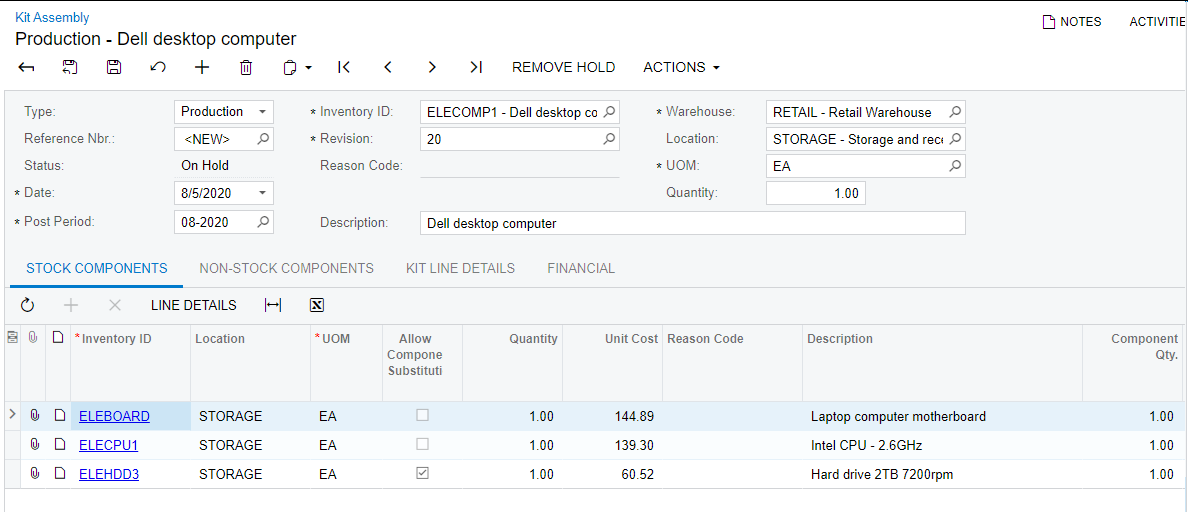

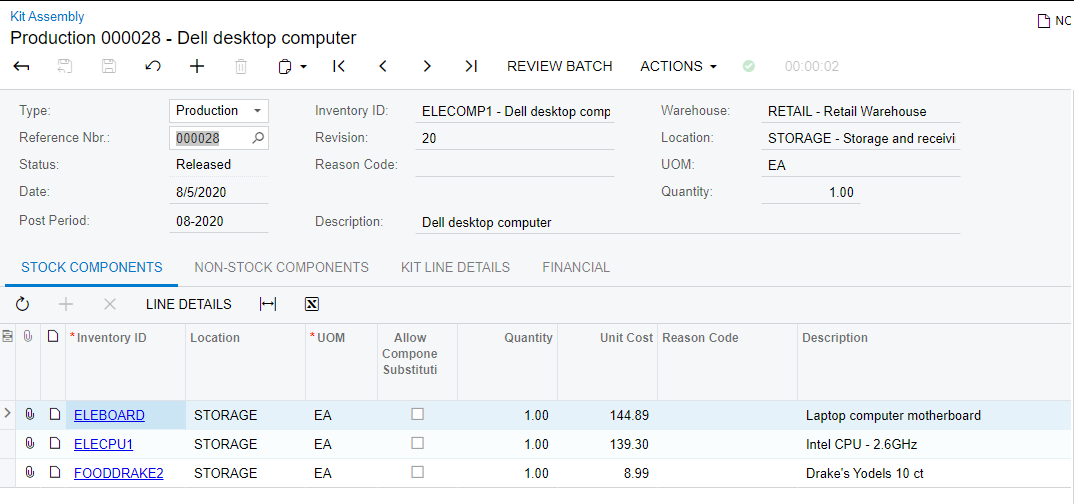

Setup some stock skus to use related items (set the item class to NOT allow Negatives) and tried to assemble a kit that one of the components was at a qty 0, and had allow for substitutions but I’m not sure where I pick the substitution item to add to the Kit assemble BOM. Is there something I’m missing in the process? How do I process the substitution?

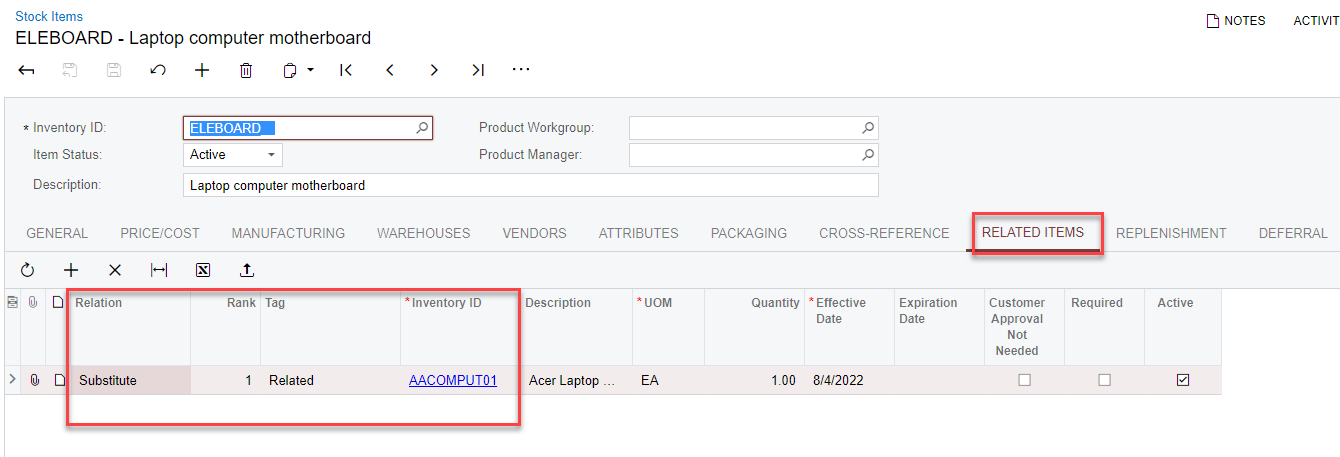

Best answer by Kandy Beatty

View original