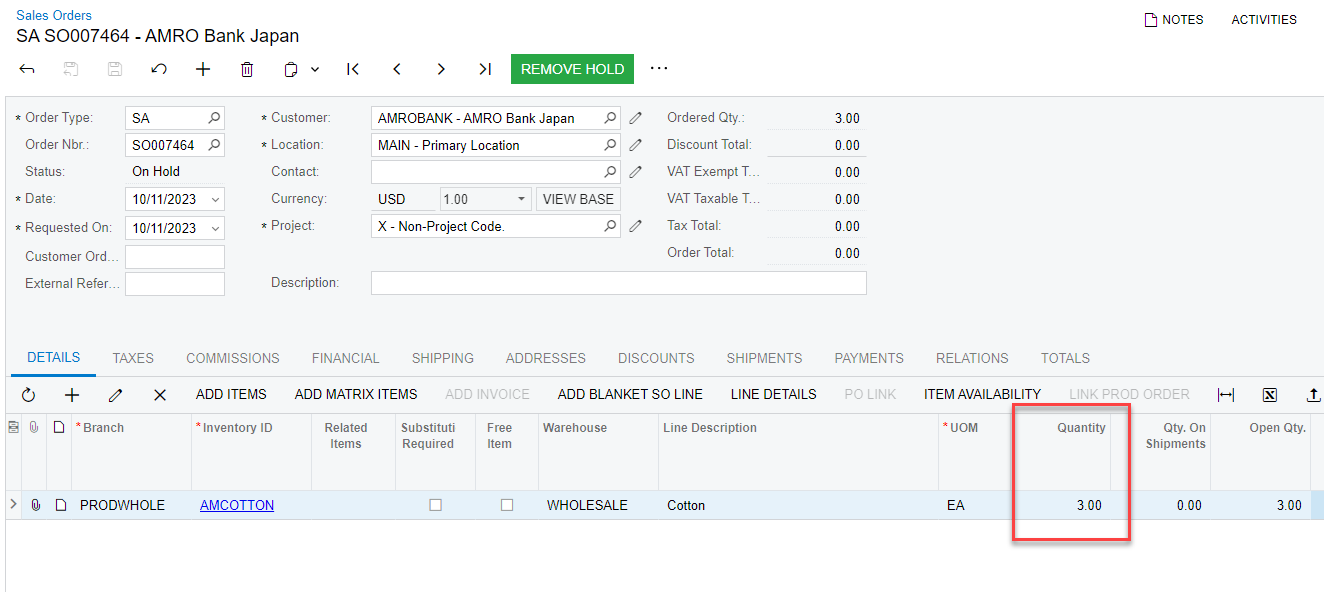

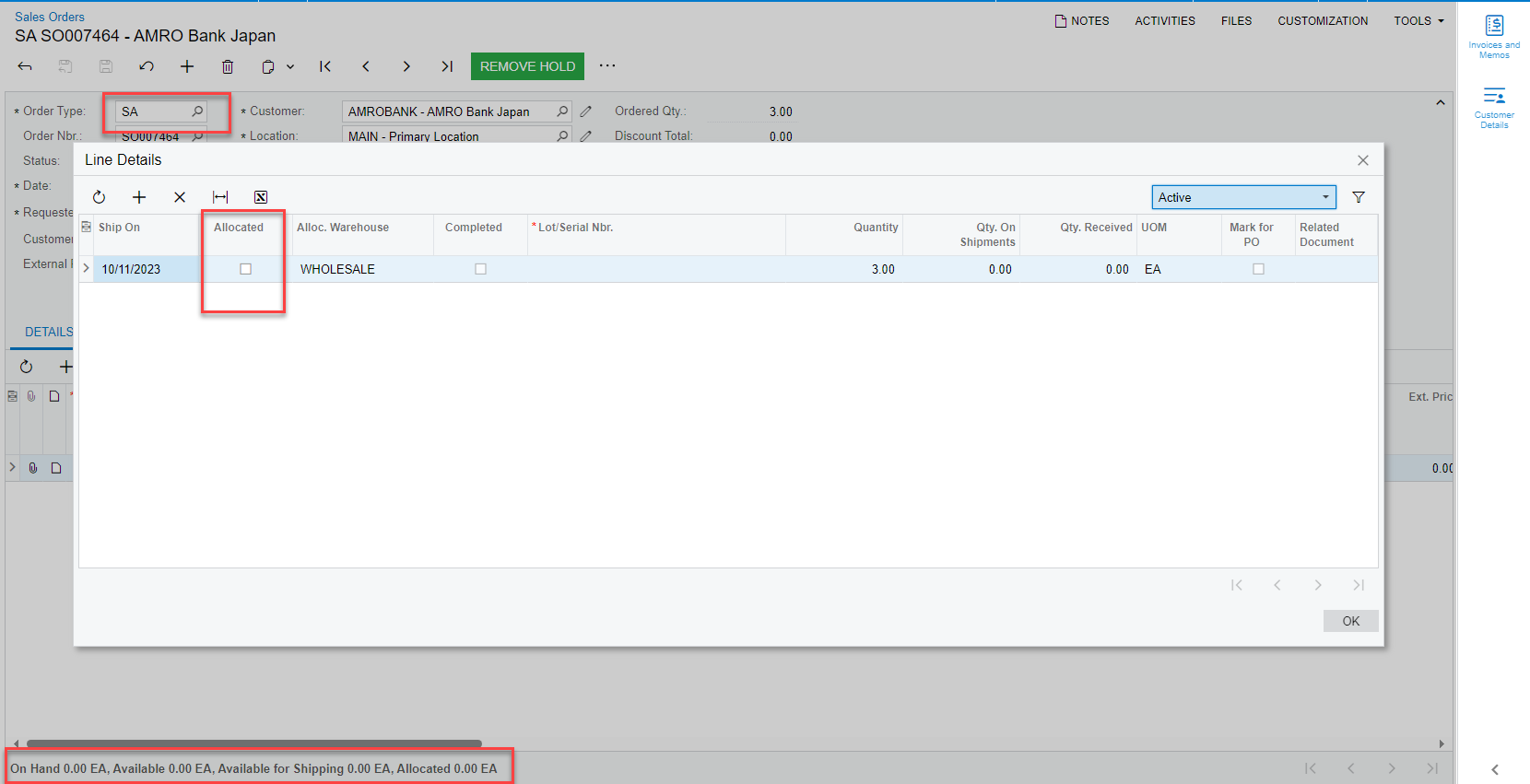

We have an issue wherein we may enter part of a Sales Order, or the full order, and then place it on hold awaiting some further information. The Sales Order may be on hold for several days. We are on 22R1 Build 22.119.0027

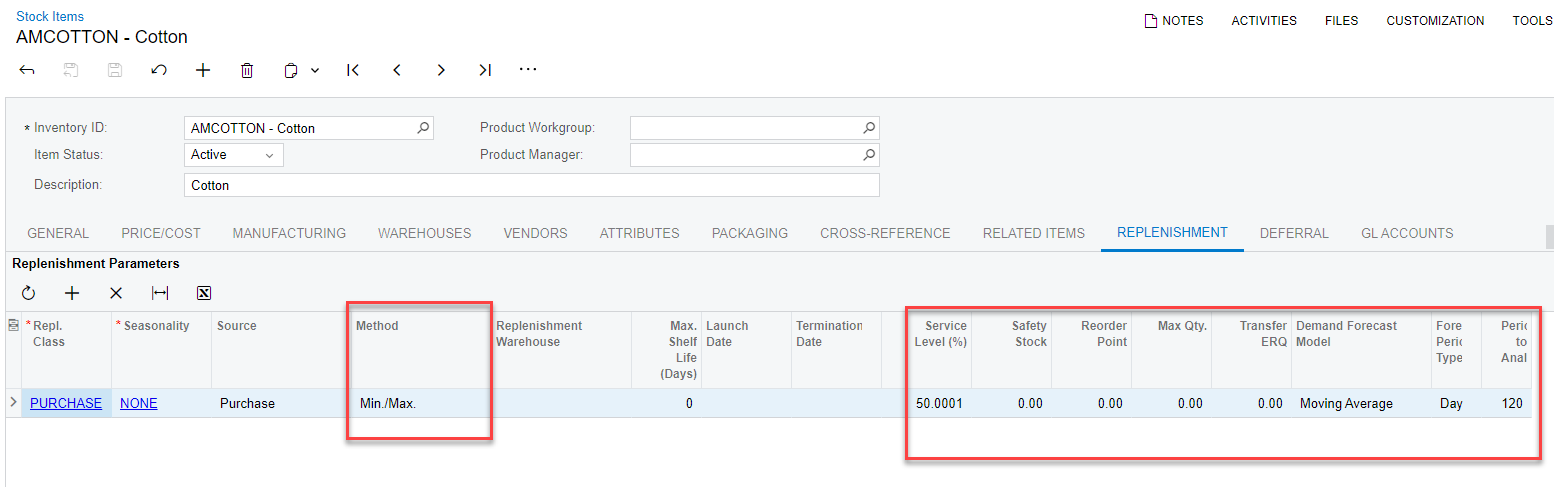

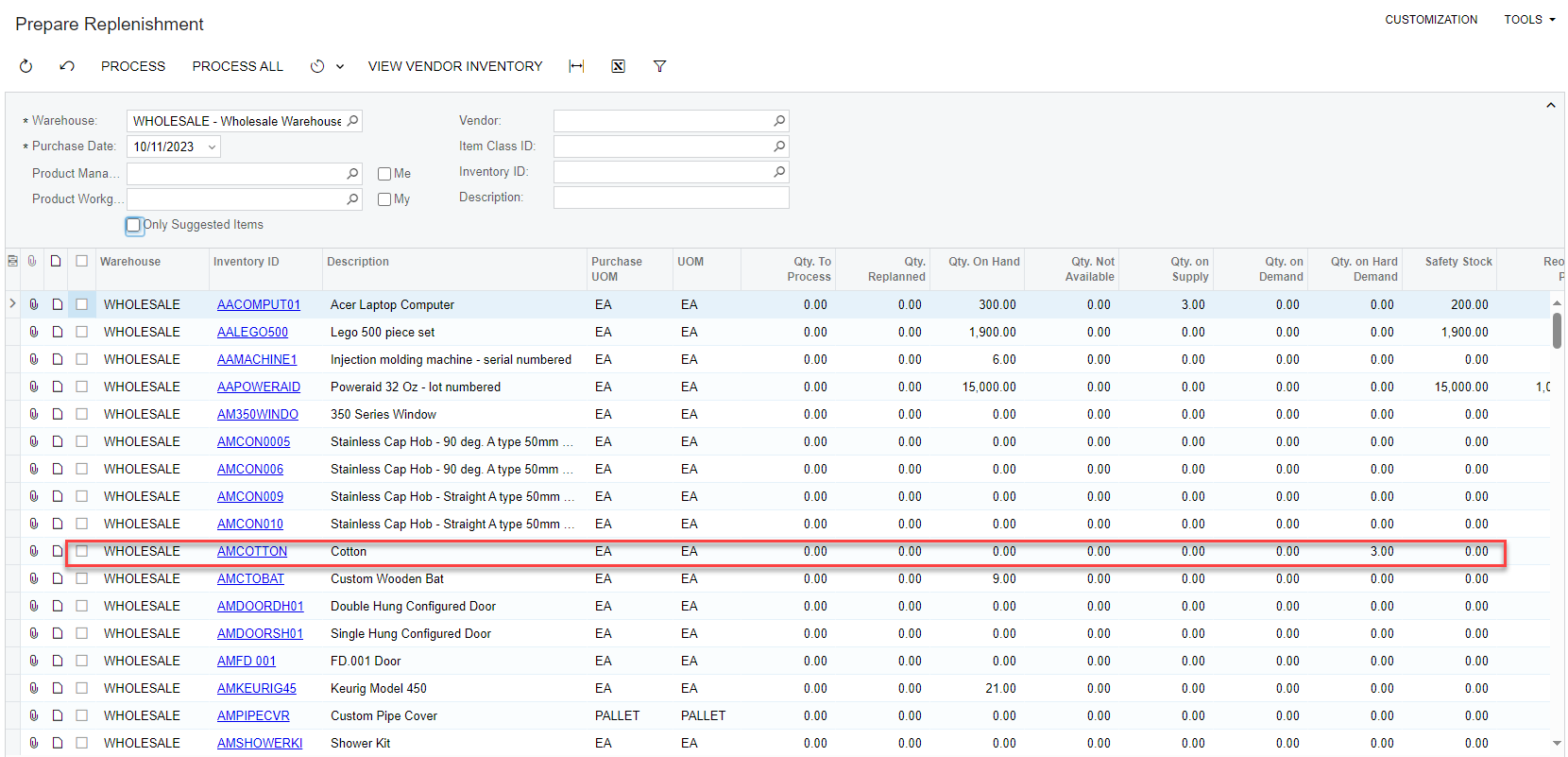

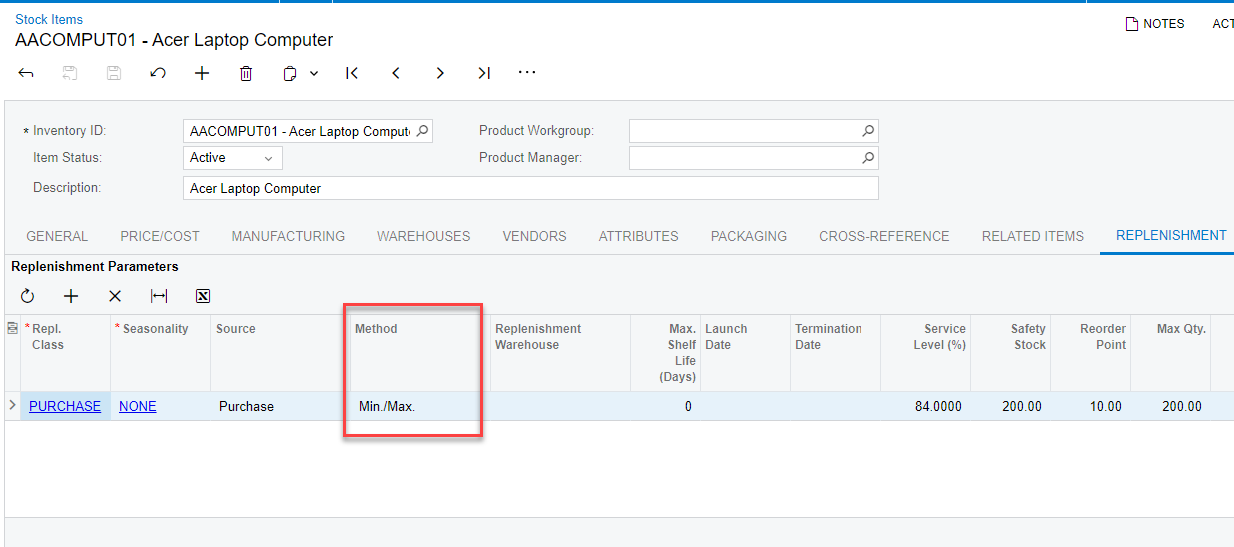

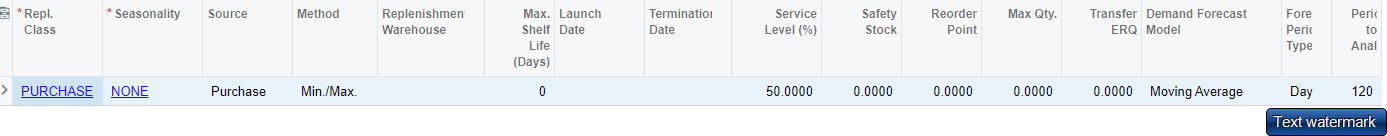

When you go to Prepare Replenishment, however, the replenishment calculation seems to include all orders, including those on hold, in the demand numbers. This can cause inventory buyers to purchase items that may not be needed because we have changed the Sales Order lines or quantities before releasing it from On Hold status.

Is there a setting to have Replenishment ignore demand from On Hold Sales Order, much like the Inventory Availability Calculation Rules can be configured for various scenarios. Alternately, it would be useful to have a “Draft” Sales Order Status where the order is not visible at all to other modules in the system until the Sales Order is released.

Has anyone else struggled with this scenario or had successful workarounds? Thanks in advance.