We are using Item Replenishment now. And it works great. We want to add Item CLASS replenishment. We need help with understanding how Item CLASS replenishment works. For example,(1) in the Item CLASS settings tab, we do not see any MIN / MAX settings. Where are these MIN / MAX setting set? (2) how does Acumatica know which item in the Item CLASS to reorder? Does the system look to the ITEM replenishment to get the MIN / MAX amount to create the Item CLASS replenishment? Thank you fo your help.

Solved

Help with Item Class Replenishment

Best answer by Kandy Beatty

Hi

There is no min/max on the item class. You still will need to setup the Min/Max on the individual item. The class is just the basic settings.

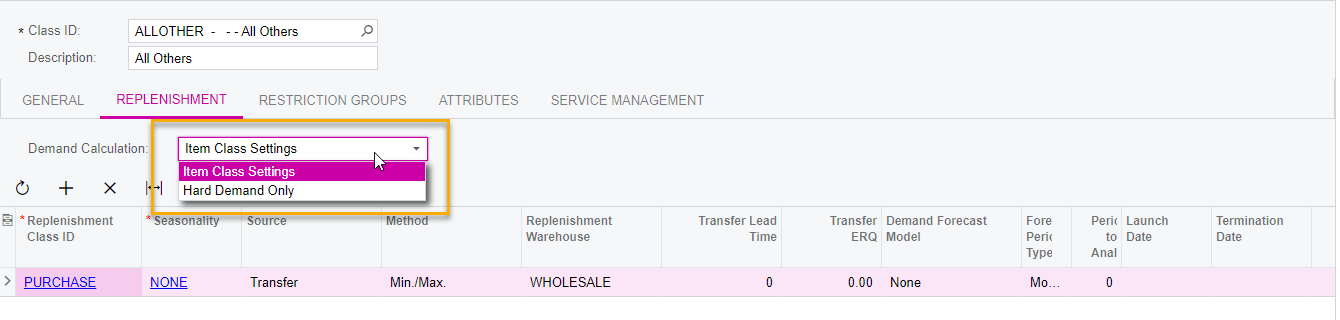

There is the following options:

- Item Class Settings: Demand will be calculated based on the availability calculation rule specified for this item class on the General tab of this form. Documents of the following types may be involved in the demand calculation: sales orders, transfers, and kit assembly documents (of the Production type).

- Hard Demand Only: Demand will be calculated as (Qty. SO Allocated) + (Qty. SO Back Ordered) + (Qty. SO Shipped).

Acumatica supports replenishment at a fixed quantity and replenishment between the minimum and maximum quantities on the stock item.

The system does not look at the item class for replenishment. When you are preparing replenishment, you can simply choose all the items of that class to replenish.

Enter your E-mail address. We'll send you an e-mail with instructions to reset your password.