Hello community,

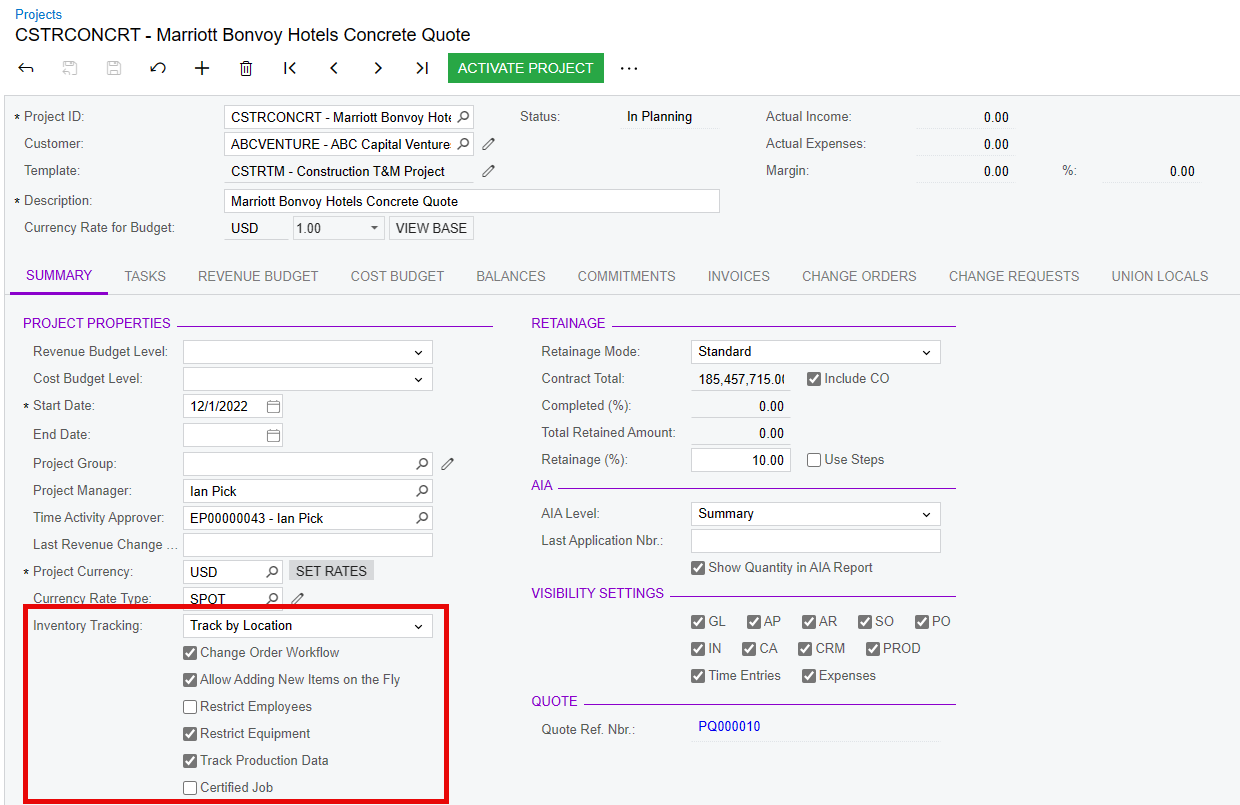

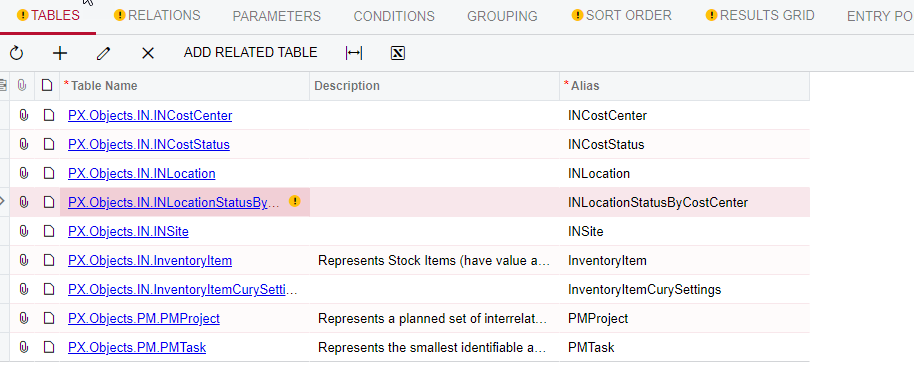

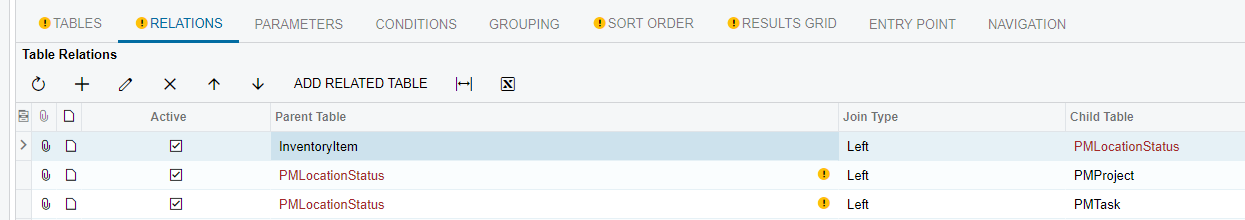

I would like to know how can a user allocate a specific inventory for a specific project. i am looking if Acumatica can allow us to allocate qty for future purposes for a particular project.

Thanks in advance.

Best answer by Kandy Beatty

View original