Am I missing something when I’m scanning materials to a production order?

The workflow for using a scanner has been (in other modules) you scan your location, item, then you get this fun kind of conditional branch:

You can set the qty, scan a different item, or scan a new location.

When scanning in a production order, once I’ve scanned an item, I am forced into one of two paths:

Set Qty or Scan Production ID.

Why am I not allowed to scan another item, or another location for another item in the same Operation in the same Production ID?

Instead of making nice loops, I’m forced to scan:

- Production ID

- OP ID

- Location

- Item

- Set Qty

- Confirm Form or repeat from Step 1.

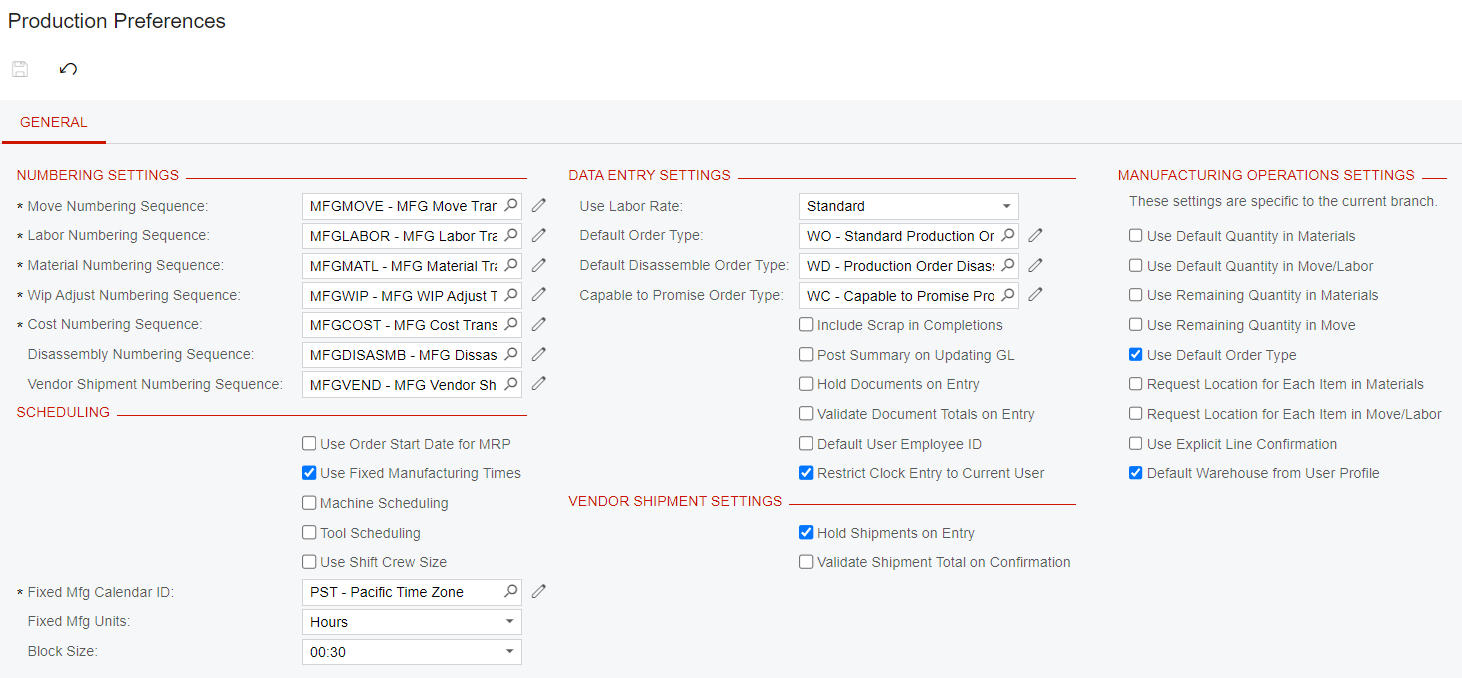

I want to repeat from Step 4 (or 3 as needed). Is this something I need to configure? Seems weird to keep feeding the system “header info” when it already has it. Sure, I can see issuing material to multiple Production Orders, but that shouldn’t be a forced thing on the end-users. In the system I’m using they will NEVER issue to multiple production orders.