We are using sales orders to process sales. The sales come by Shopify, API (woo commerce) and manual. Creating sales orders works great!

Where we struggle is returns/order changes. Our most common situation removing an item from the sales order that is not in-stock followed by partial credits.

Currently:

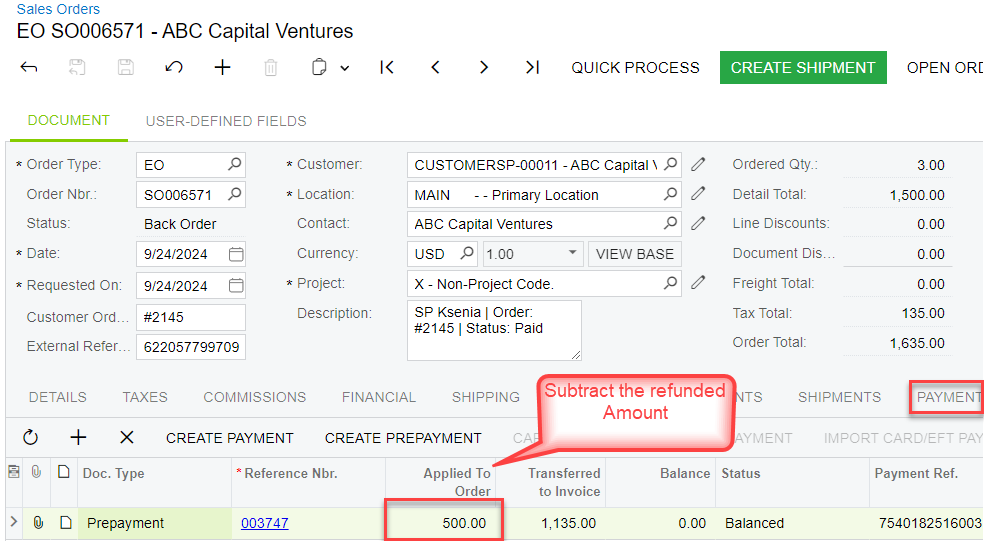

Step 1: We go into the sales order and remove the item that is not in-stock. Then we add a non-stock item to the order for exact same amount. Create the shipment, ship it and invoice the order. The reason we add a non-stock item is the order comes in with a payment. If we don’t close the order for the exact amount the payment remains open with balance.

Step 2: Since it was paid order we credit the customers credit card on Woo Commerce or Shopify. Then we go into ACU create a return order using the non-stock item with amount of the item removed and any tax. Then we create a refund payment in ACU, attach the payment to the refund order, lastly invoice.

Situation 2: As a customer service we may give a customer a refund for $5 (example). The refund is not tied to an item. In this case we have to create a return order using a non-stock item, create a refund payment, attach the payment to the return order, then invoice.

The current process makes everything tie out but is not easy. We can’t make any adjustments to the original payment since it has to tie to the bank rec.

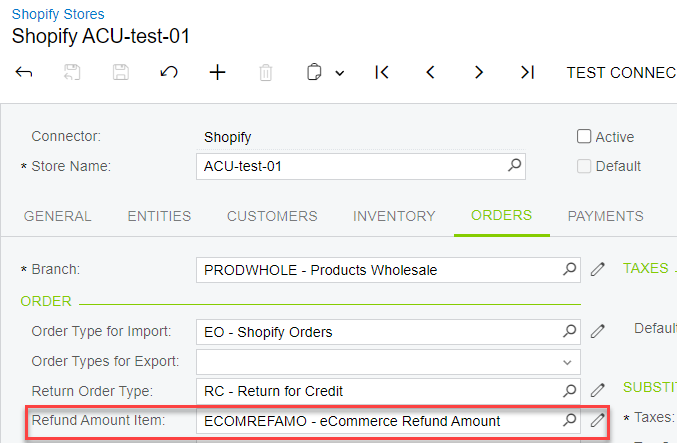

I know Shopify (ACU commerce connector) has a refund process, however it doesn’t help us in adjusting the original sale. In many cases the refund payment doesn’t sync. We choose not to use the Shopify refund since we have orders coming in through an API for our Woo Commerce site. Adds confusion to have different process, not to mention the Shopify refund needs hand holding.

Business background info: We have many websites (20 Shopify, 23 Woo Commerce, 15 custom gifting platform). We produce branded goods for companies, build the company a website and or gifting platform to distribute the goods to the employees of the company. Similar action would be a 3PL company. We store the products in our warehouse and distribute when ordered. Volume of orders is between 2,000 and 5,000 monthly, with120 orders needing adjustments per month.

With volume the current process is very manual and time consuming. Appreciate any feedback/ideas to make this process better.