When scanning multiple Materials in one Scan Materials session, it defaults the quantity on the first line, and from there on out it only records quantity one. For example, I have a work order that contains qty 4 EA of three different items. Scanning the first item records an issue of qty 4. The other two items only have issue qty of 1. I have messed with Production Preferences related to bar coding to no avail.

Solved

Scan Materials Glitch?

Best answer by angierowley75

The Use Remaining Quantity should work as you are suggesting. The fact that it is defaulting the second and subsequent lines to quantity of 1 instead of quantity remaining is incorrect. Please log a case with Support.

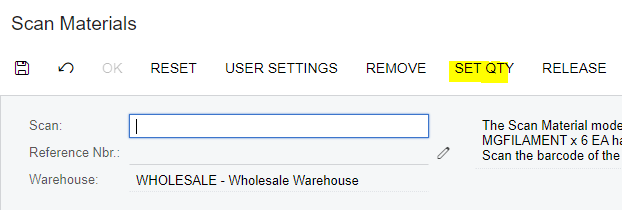

The SET QTY button on the browser is on the Action Bar

On the Mobile Scan Material screen “SET QTY” is a button at the bottom of the display. You may have to swipe up from the bottom to get the list of buttons to display.

Enter your E-mail address. We'll send you an e-mail with instructions to reset your password.