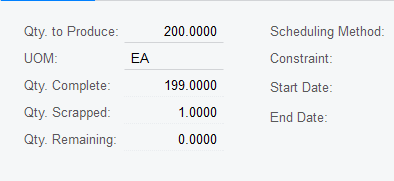

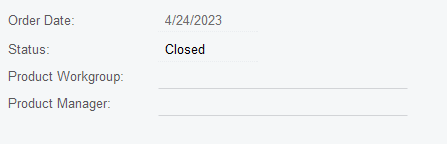

I need help to figure out whats best to handle a production order that has been closed and still says there’s a balance remaining to produce even though you have scrapped some of the order that needed to be fulfilled and we don’t wish to issue more material to complete the order.

For instance we wanted to produce 10 nozzles and issued the materials that were needed to full that order but 2 of them were damaged in the process. In the move transaction we moved the 8 the were completed and in the scrap section we put 2. Since we produced 8 and cant issue anymore material.

What would be the best way to approach something like this since someone closed the order and can’t back track it?