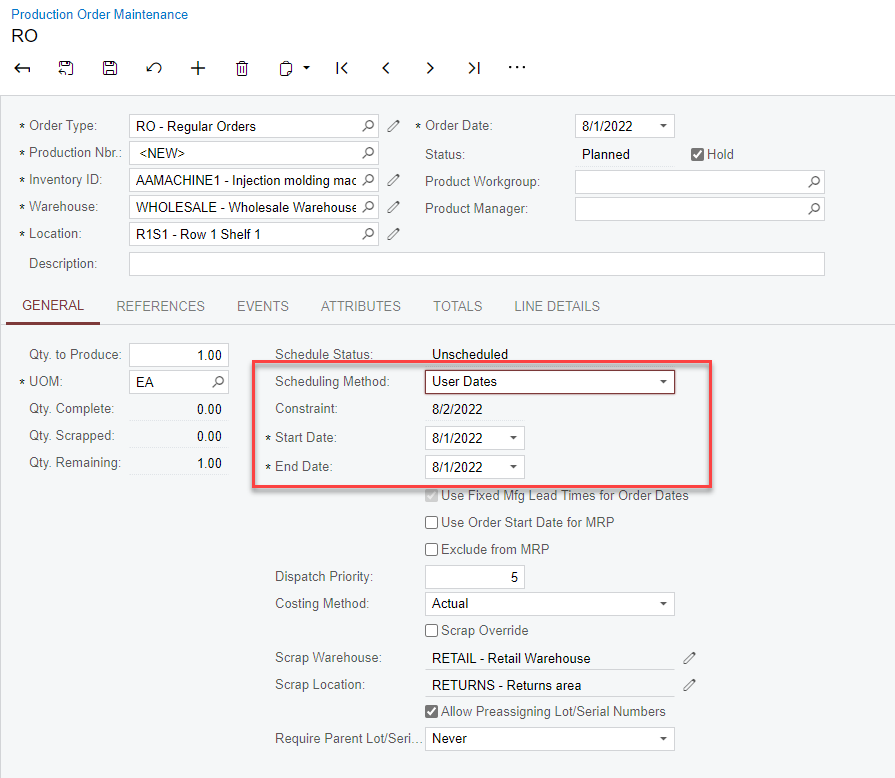

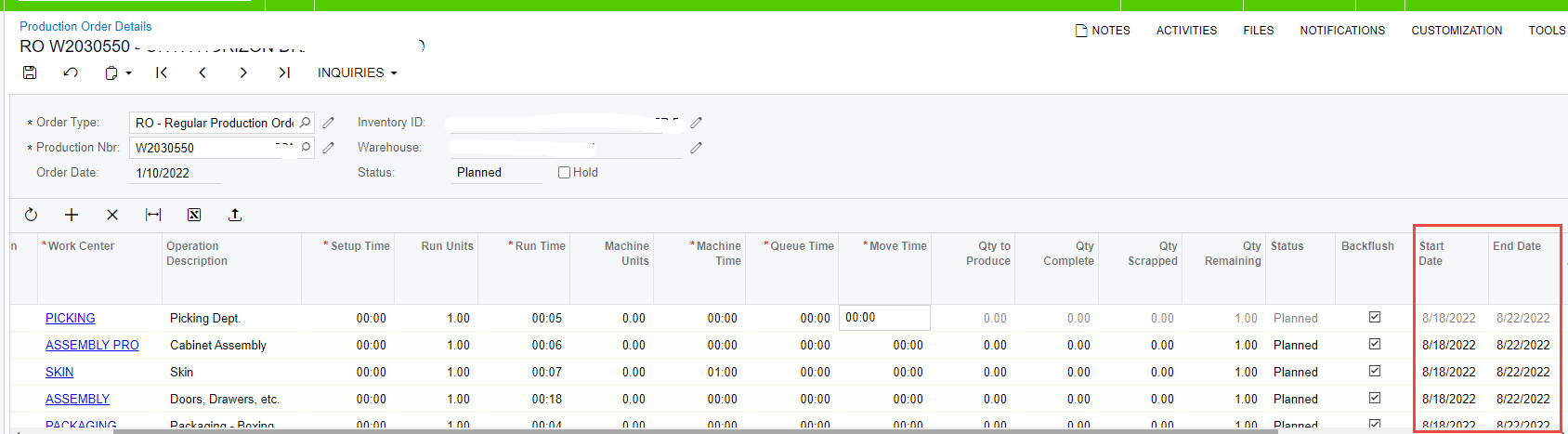

Would anyone know if there is a posibility to update the start/end dates on an operation itself? i know you can update the actual work order but i would like to have seperate dates for each operation so each team have there own start date.

Thanks!

Best answer by Debbie Baldwin

View original