It looks like there has been a major refactoring of how line splitting works in Acumatica, which is great news because this moves us away from the old kvstore approach, which was not performant at scale.

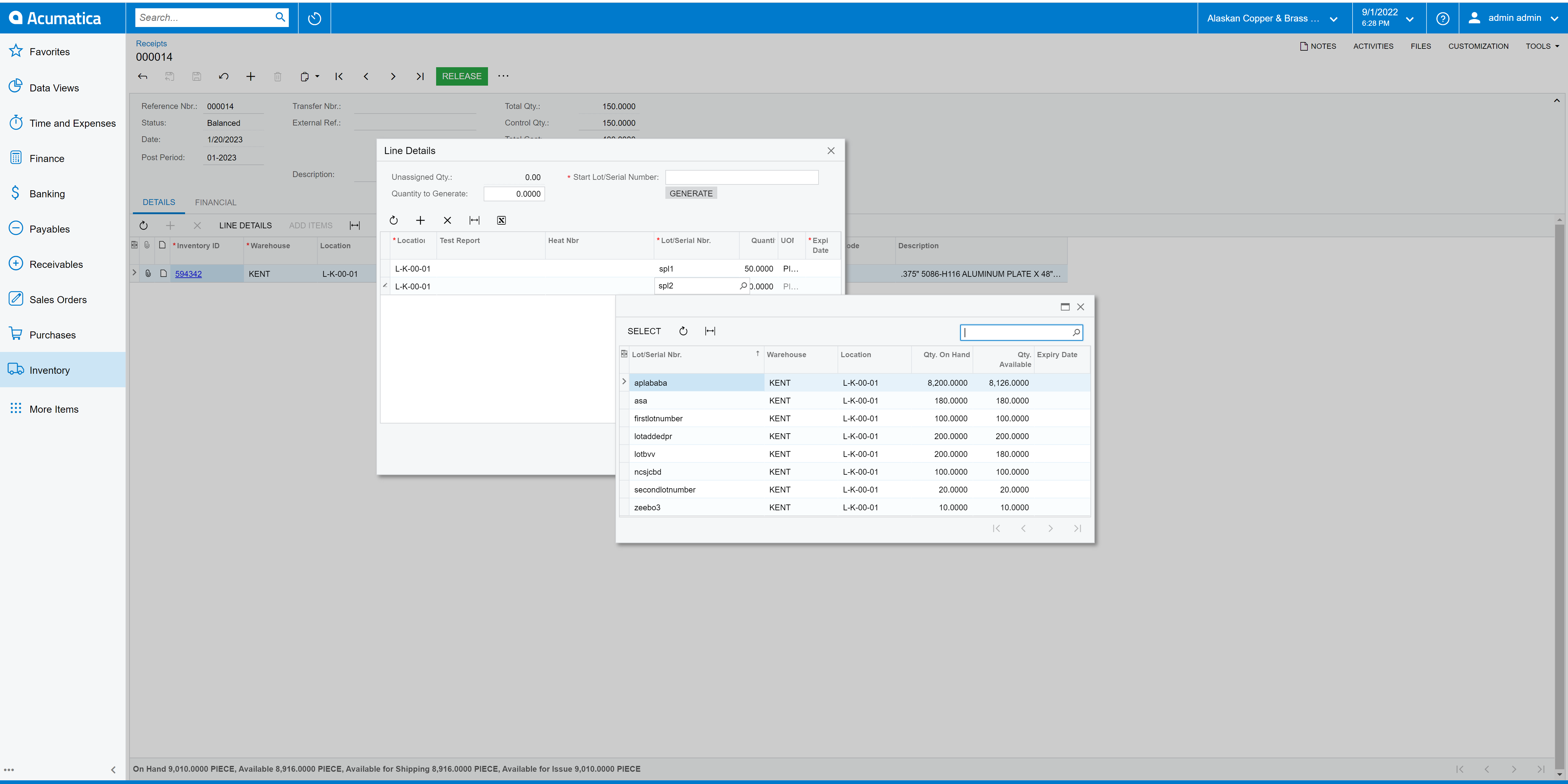

However, there seem to be zero practical examples of how to implement this functionality. For example, let’s say I want to add a field to POReceiptLineSplit, and then pull that field back in a SOSalesOrderLineSplittingExtension. How might I do that?